Matthew Jensen of architecture and interiors consultancy Fraiserline explores the challenges of applying BIM to cruise and ferry ship design, to serve the needs of architecture, interior, product and naval professionals

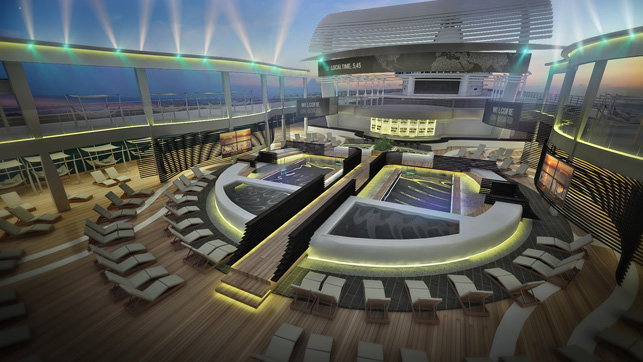

Superliner cruise ship

The early passenger ships of the late 1880s shared many of the same attributes of buildings of that period, being designed with the grandeur of neo-classical architecture in mind. While the architects and design teams involved were primarily naval specialists, the interiors of these vessels boasted the same kinds of ornamentation that were seen on buildings and those involved would work with hand-drawn blueprints and then technical drawings to fit out lavish interiors during shipbuilding.

Since then, much in shipbuilding has changed, just as it has in building design – not least the introduction of CAD, which has transformed approaches and design-team duties. Information technology has boosted collaboration, enabling design teams to digitally coordinate files between shipbuilding yards and fit-out contractors.

With overlays for each specific discipline, shipbuilding specialists are able to quickly appraise the construction of a passenger liner in great detail and, just as they would do in building design, appoint architects and interior designers, along with engineers and project managers.

The spatial arrangement of modern liner fleets, meanwhile, is typically dictated by the standards of the individual operator, and will take into account ship type and specifications for a given ship’s infrastructure and systems. Cruise operators will often nominate a shipyard that provides a standard catalogue of interiors and suppliers.

Unlike aircraft cabins and rail carriages, where designs are the result of parametric modelling and often validated by the OEM, interior designers working on cruise and ferry ships rarely use this technology. In fact, many continue to rely on 2D CAD systems.

Passenger deck visualisation

BIM – architecture meets ship building

At Fraiserline, our roots are in architecture, but we have merged this expertise with shipbuilding and developed a niche for ourselves: interior design for cruise liners.

Since 2016, we’ve helped innovate passenger liner fleets belonging to a range of operator brands. Throughout this process, we’ve continually explored a vital question: can BIM be applied to this world of cruise and ferry ship design? In other words, can BIM go beyond buildings?

This is important, because our biggest challenge has been working alongside carriers to appoint a suitable digital design system for efficient collaboration and teamwork. Our initial investigations showed us that marine engineering companies work with a wide range of design tools, ranging from 2D CAD to the latest versions of 3D parametric systems.

Recently, I was told by an industry contact that Royal Caribbean International has started to use BIM in its shipbuilding department.

To me, that makes sense: some naval attributes of passenger ships may be hard to incorporate into BIM, but the building-like elements would seem to be a good fit.

Typically, tools such as SolidWorks have been used for masterplanning naval architecture and have provided better features than 2D CAD. In addition, the coordination of specialist teams needs improvement, which would seem to welcome the collaborative advantages of BIM, to automate, improve and streamline the design-to-deliver process.

Siemens PLM has gone a step further and developed specialist software for shipbuilding.

This is already used by companies such as Daewoo Shipping, Hyundai Heavy Industries and Sunseeker International. It includes a number of specific features such as ship structural analysis, alongside materials data and mechanical and engineering tools.

However, when you look at a large marine project such as a cruise liner from the perspective of a building, it doesn’t provide a teamwork platform that is capable of supporting all disciplines throughout the build process.

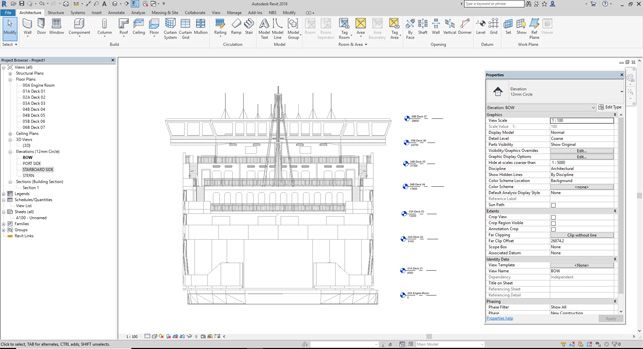

Applying Revit to marine projects

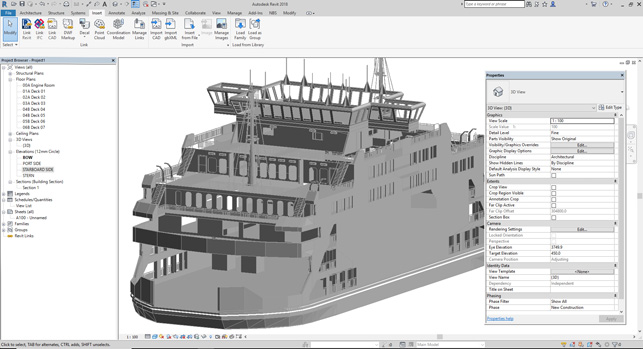

Recently, Fraiserline began moving its core architectural design projects onto BIM, in order to ease efficiency and productivity in the office. This was a prime opportunity to test the capabilities of Autodesk Revit, to see what it could bring to the cruise ship industry.

Having recently undertaken a number of refurbishment contracts for global superliners, we have found that many design teams supply project data as SolidWorks or IGES files. In some cases, we have received point cloud internal surveys.

With the idea in mind of piloting Revit for a superliner refit, the import of SolidWorks files has been successful. They can be cleanly organised by Revit ‘families’, in a similar way to managing the import of point cloud data files.

While most attributes of parametric CAD/CAM files are not fully editable or transparent, they can be referenced to represent another team’s design elements efficiently within the BIM environment.

This has given our designers a quicker and clearer understanding of the proposal in three dimensions, and enables us to parametrically model a solution in real time for sign-off and approval. In some cases, it allows us to undertake quick CGI simulation visuals.

As a small business, pushing BIM to support nonbuilding related projects has at times been taxing, even frustrating. While trying to migrate various parametric model formats supplied by other parties, improvising tools has been near-impossible for non-standard components in BIM, such as the watertight bulkhead doors mandated by marine regulations.

Also, a ship’s structure is primarily steelwork and, as such, can link to the superstructure orders of Revit, but does not validate ship performance standards, structural assessment, or construction methods – the things, in other words, that differentiate a ship from a typical building structure. This is down to the current limitations of BIM.

But the fact remains that the overall mantra of BIM – the ability for team members to collaborate and to coordinate their efforts effectively – are very relevant to the cruise-ship design sector. Building-related vocabularies in BIM could certainly be adapted to cruise-ship megastructures and correlate with other engineering software with ease.

And regardless of hurdles, the end result of BIM has still proven to be commercially beneficial as compared to former practices using 2D CAD software.

Ship design as seen in Revit

Passenger ship Revit model

BIM – finding a middle ground

The fusion of parametric product design software and parametric architectural software certainly has the potential to reshape the way in which large passenger ships are built.

The latest BIM and parametric design software products, after all, include metadata capabilities that link to materials and specifications in order to provide a live inventory of product information. That could prove very valuable in our industry, if it adopts BIM.

Alternatively, there may be an opportunity here for new software tools to emerge that more specifically address our industry’s collaboration and coordination needs.

Either way, the question remains: How will we build the superliners of the future and what design tools will we use, if not BIM, to make sure these complex projects are successfully delivered?

About the author

Matthew Jensen, founder of Fraiserline Architecture, began his career in civil engineering before moving into architecture, working across high-end residential and hotel projects.

Over the past five years, Jensen has developed relationships with leading brands in the cruise, marine and aviation sectors and in 2017, he set up a subsidiary business that introduces engineering, architectural, transport and construction companies to parametric modelling systems including BIM.

BIM in marine design

Default