It’s been quite the year so far for Al Dean but he’s got a feeling that change is in the air. Are we on a cusp of a new era of design and engineering tools that will allow us to do things differently from how we did them before?

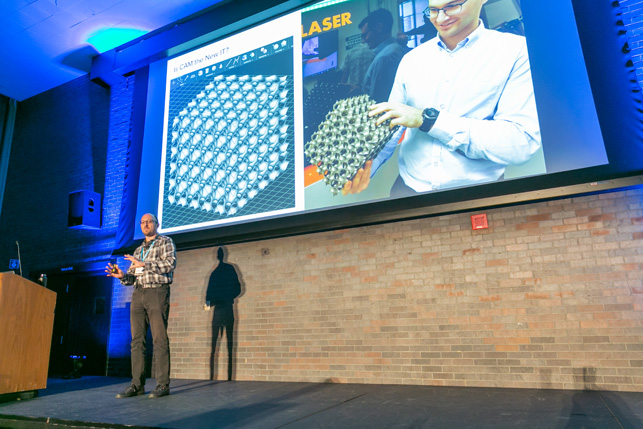

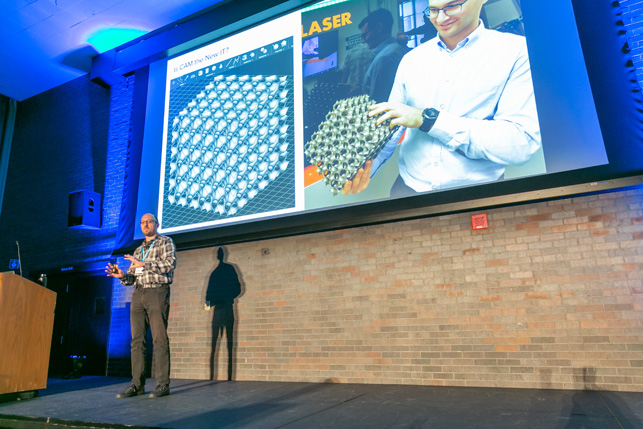

Blake Courter, previously founder of SpaceClaim and now head of product at nTopology, presenting at D3D Live, Boston

Let’s be honest, the vast majority of the world doesn’t really give two shits about 3D design software.

Even many of the vendors that have previously talked about it and developed tools at length don’t really care that much about it any more: They’ve moved on to seemingly richer pastures, the world of the Internet of Things, the world of experience design, or whatever.

But in the last two weeks, I’ve been to three events that have shown just how important are the core tools we write about in this magazine.

At its heart, 3D design and engineering technology is enabling us, as a profession, to break new ground with every year that passes.

After all, while we can talk about a new world of privatised space travel, of autonomous vehicles, of medical device breakthroughs, when all is said and done, there’s always a team of designers and engineers developing these products and bringing them to market.

The first event I’m referring to was held by Siemens in Cambridge. Not by the NX or Solid Edge teams, but rather, the company’s component business; namely, Parasolid, D-Cubed (and now Lightwork Design).

There, I got to see where things are heading with the technology that underlies many of the tools we all use today – and there are some incredible things coming down the line that will assist not only in using meshes more closely with solids and surfaces, but also in enabling us to build new workflows around scanned data or complex point clouds.

It’s also clear that many vendors are still looking to build new tools and explore new areas for their own toolsets, whether that’s to make modelling more robust or to explore new areas.

The second event was held at Coventry’s MTC by the folks at Altair. This event focused on additive manufacturing and there were some serious chops on show.

Examples: the folks at GKN discussing flight certification for metals additive (in short, difficult, but they’re nearly there), and the team at Surrey Satellites, who use additive metals and smart design for part consolidation on satellites already in orbit. Simulation of both the performance and manufacture of such parts is clearly fundamental here.

Finally we come to our own DEVELOP3D Live USA event in Boston.

It was pretty clear that some established CAD vendors are actively exploring some entirely new ground.

There’s Siemens, for example with its work on electromechanical integration. PTC, meanwhile, used our Boston event to show off its new integration with Ansys’ Discovery Live. (And there will be more on this to come in DEVELOP3D before the end of the year).

At the same time, there were also new entrants such as nTopology and Frustum, who are developing new systems from scratch that take a radically new approach to geometry design,more closely linked to production methods than ever before.

Stay tuned, folks. It’s all about to get very interesting indeed.

Are we on the cusp of a new era of design and engineering tools?

Default