Specialist vehicle manufacturer Waimea has streamlined its configuration and quoting with the integration of Driveworks CPQ, as Gabrielle Brown reports

Building specialist utility vehicles for varied industries to carry out specific, challenging jobs can be complex. Manufacturers need to keep up with configuration demands, the cost and availability of resources and regulatory compliance, all while maintaining efficiency to make a profit.

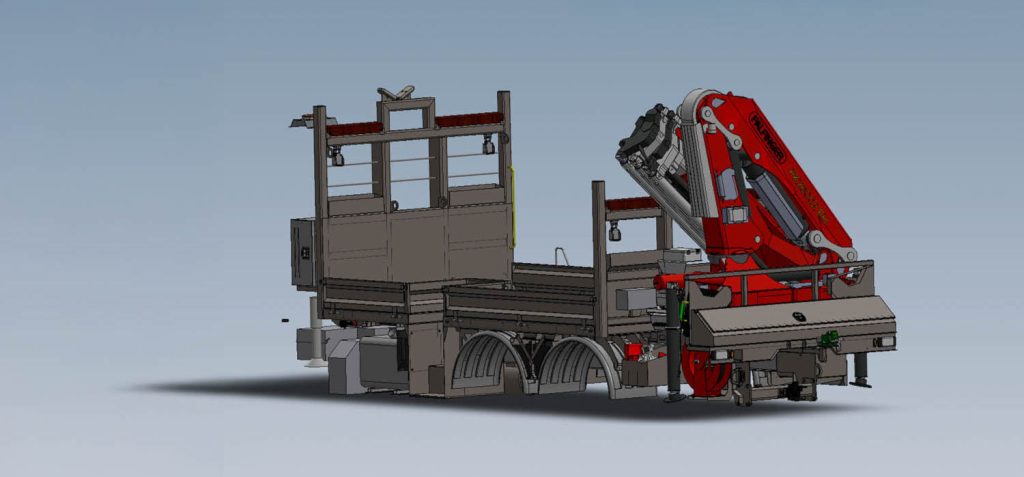

New Zealand-based designer and manufacturer Waimea makes specialty vehicles used across a range of industries, including in power, forestry and road and traffic applications. The company needed a system to enable its sales team to configure and manage a wide range of custom vehicles accurately and at scale.

“It’s all very well to be able to design and build a truck,” says Waimea data and systems administrator Alan Mohekey. The hard part, he continues, is capturing all the necessary information so that a sales executive can configure a truck in the way that the customer wants and deliver that information to designers so that they know what’s required, too.

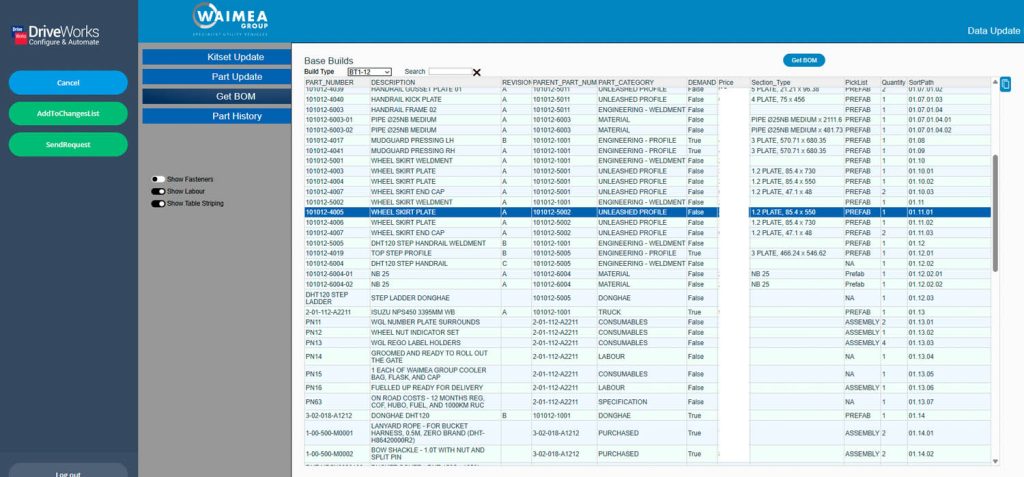

Waimea had previously managed configurations using Excel spreadsheets, but with 30 possible combinations of trucks and equipment, each requiring its own spreadsheet of hundreds of rows, this approach quickly became unmanageable.

Driveworks CPQ // Configuration station

To tackle the problem, Waimea adopted Driveworks’ CPQ (Configure, Price, Quote) software. This enables its sales team to intuitively configure vehicles and to provide accurate quotes. Guided selling technology, meanwhile, means they can quickly configure custom vehicles with viable optional extras.

Waimea has implemented Driveworks across its workflow. This integrates with the company’s primary SQL database (MSSQL), its warehouse software (Unleashed), its CRM (Pipedrive), its CAD database (PDM), its 3D CAD software (Solidworks) and its online forms system (SmartSheet).

Waimea can add its own compliance and regulatory requirements into its set of design rules within Driveworks, ensuring each custom product complies with relevant safety standards. Each job automatically generates .csv and .svg files, creating accurate tables and diagrams based on user input.

With added component costing, the sales team can provide customers with fast, accurate quotes, increasing the likelihood of a purchase.

The integration of Driveworks has improved accuracy and reduced the need for rework, streamlining processes and maximising sales for Waimea and ensuring its customers can get the job done.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here