When Markforged announced the combination of a lower cost machine with its Onyx chopped carbon fibre material, we got a bit excited. Al Dean looks at how the Markforged Onyx One entry level machine stands up to its bigger brother

We’ve covered the Markforged nylon and carbon fibre machine, the Mark Two, extensively in the last few months (Click here to read the first part of out Markforged Mark Two Review, and here to read the second part of the Markforged Mark Two Review).

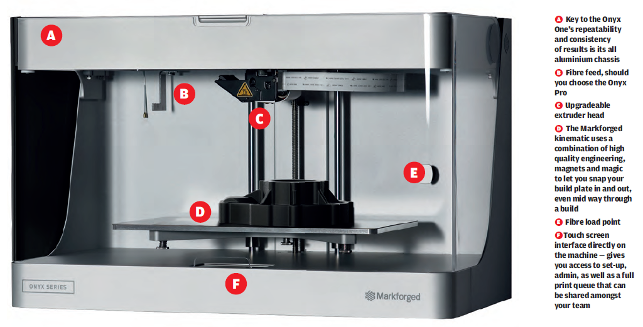

No plastic here. The build quality of the Markforged machines is something that is unmatched at the desktop level

The ability to mix a nylon-based material with single strand fibres (including carbon, glass and Kevlar) certainly impressed us.

At the time of the review, however, the company also announced two new products that didn’t make it in. The first is a new material, called Onyx, which brings two key things. Firstly, the material is a mix of nylon and chopped, micro particles of carbon fibre. The operating temperature and stability of this material looks interesting for a variety of applications.

Secondly, it’s also the first matrix material that isn’t white, so those looking for under the hood or more industrial uses of the Markforged process have a material that both looks and performs the part.

The second announcement, linked to the above material launch, is the Onyx One.

This is a step away from the core focus of Markforged — plastics with single strand fibre reinforcement — and focusses on the building of parts with just the Onyx filament. One print head, one purpose, one machine — at a dramatically lower cost.

We’ve spent the last couple of months getting to know the Onyx One, exploring its capabilities, so let’s dive straight in.

Out of the box and set-up

Compared to the set-up process for the Mark Two, this is a lot more straightforward and efficient as you only have one extruder nozzle to level to (on the Mark Two, the second nozzle is for the fibre reinforcement materials).

Once you’ve extracted everything from the box and familiarised yourself with the constituent parts, you need to run through the set-up. As ever, this is a case of powering up the machine, connecting it to the network and running any subsequent updates to the firmware.

You’ll also need to attach the Pelican case and feed tube that takes your Onyx material spool and filament from an airtight container into the machine. The whole process takes around 15 minutes, by which time you’re up and running.

One of the key strengths of Markforged machines is the build platform, featuring its three point magnetic mechanical fixturing. Essentially, due to the robustness of the build quality and some fine engineering work, once you’ve worked through the bed levelling process, you can pretty much leave it alone. We’ve not relevelled the machine in our office in about three months since installation (though once a week might be good practice).

Print preparation with Eiger

To get your machine running, you need to access the pre processing software.

In the case of Markforged’s machines, this is done through its cloud-based file import and job management system, Eiger.io. Here you can upload STL geometry and process the build parameters.

These range from standard controls such as layer height, in-fill pattern (you have a choice of triangular, hexagonal or rectangular) and wall thickness options, as well as a range of editing options.

By switching to the ‘Internal View’, it’s possible to further tweak these settings, so you can add material where it is needed and remove it where it isn’t.

Eiger also gives you the build management tools — and these are key, particularly for those looking to use the machine for industrial purposes.

While each STL is treated as a part and processed individually, these “parts” can also be organised into both projects and individual builds. This allows you to create a set of parts and store the build job for re-running whenever needed.

There are also branching and revision management tools, allowing you to replace individual parts, manage design variants and the like.

When combined with the remote monitoring and job queuing system, it’s a capable management system targeting the production of parts — something that is unique among most 3D print vendors, never mind at the desktop level.

Once you’re ready, you can either send it to the machine directly (assuming that it is free) or add it to the queue (which is accessed through the machines’s control panel).

The results

The Onyx One is a very different beast compared to the Mark Two we looked at previously. There isn’t any of the single strand carbon fibre complexity of set-up — it prints with one material and one material alone (though presumably Markforged has the option to add additional filaments at some point in the future). Being a single material build process, this typically means issues with support removal and reduction in surface quality.

While the parts that come into contact with the supports do have a less than optimal surface, it’s much better than many similar systems. This is partly down to the material itself (which has thermal benefits from the carbon filler) and partly down to the support generation algorithms. Markforged does a very good job in this regard and the support material peels away easily and without impacting surface quality too greatly.

The parts themselves are incredible. The surface finish is bang on, but what really makes them impressive is the inherent strength. Compared to other desktop level, single build material machines, the Onyx One is fantastic and the parts should stand up to some pretty heavy abuse. It’s stronger, stiffer and operates at higher temperatures.

In conclusion

My only concern with the Onyx One is the material costs, which are considerably more expensive compared to other flavours of FDM out there, and you just have one option (for now). Onyx is $189 for 800cm3 of filament.

Also, while the machine has remote monitoring (in terms of progress) through Eiger, an integrated camera and feed would be really useful, particularly for those looking to build overnight. Other than that, it’s an amazing bit of kit — particularly at this price.

We know that the Markforged machines perform well. What’s interesting with the Onyx One is that the company has looked to apply its knowledge and experience at a much lower entry level price. Considering that this machine is priced at $3,499, that’s a real steal.

No, you don’t get the additional single strand fibre option, but if you’re looking for high performance parts from a 3D printer, then this can’t be beaten at present, at that price point.

Should you want to go the extra mile and build with those more exotic composites, then the Onyx Pro is available for another $3,500.

So if you’re in the market for a serious desktop machine, this should be on your list, without a doubt.

Onyx in use: Automation components at Dixon Valve & Coupling

At Dixon Valve’s US manufacturing facility in Chestertown, Maryland, these robotic arms are commonplace in production line cells, used for part transfers in the manufacturing process.

Strength, safety and chemical resistance are key components to the company’s efficient work environment and, as such, attached to the arm of each robot is a set of jaws built using Markforged’s Onyx material.

“Dixon Valve is a manufacturer of fittings for fluid transfer industries,” explains Max de Arriz, manufacturing engineer at the company. “We’re using a large robotic arm to transfer many styles of our parts between two vertical turning centres.”

With the thousands of different valves, fittings, and gauges that Dixon Valve manufactures, each product line set-up requires custom equipment, including tooling and grips to hold specific parts efficiently.

De Arriz, along with automation technician J.R.Everett, reaps the benefits of this Mark Two machine in Dixon’s production facility. “Prior to using 3D printed jaws in the cell, we were machining each tool individually, and it would take a fairly large amount of time,” says de Arriz.

Every gripping tool needed to be either outsourced to an external machine shop or machined in-house with the manufacturing capabilities at hand.

Either way, manufacturing parts as critical as production line grippers was time consuming. As Dixon Valve primarily produces valves and fittings, these grippers also require strength and chemical resistance, as well as wear resistance from repeated use. “To that end, we utilise the Markforged parts as our transfer gripping system,” adds de Arriz.

As soon as Dixon Valve unboxed its industrial strength Markforged 3D printer, they put it to work. “We were able to re-tool a robotic arm in a manufacturing cell in under 24 hours,” comments Everett.

The Mark Two not only allowed for the production of its robotic jaws quickly, but the material capabilities of the printer, including its ability to lay continuous strands of high-strength fibres into 3D printed parts, ensured reliability in a factory setting.

“Onyx is one of my favourite materials because it combines stronger composite material with the chemical resistivity of nylon,” says Everett, referring to Markforged’s chopped carbon fibre nylon filament.

“It hits the sweet spot for us in chemical resistance and strength.”

Tech-specs

» Markforged Onyx One

» Onyx (Nylon and chopped carbon) filament

» 320 x 132 x 154 mm build volume

» 575 x 322 x 360 mm machine dimensions

» 13 kg weight

» 0.1 – 0.2 mm layers

» Onyx Material spool + build plate

» Wi-Fi & USB connectivity

» Web-based progress monitoring

» Active levelling

» 1 year return to base warranty