On the southern bank of the River Thames, away from the water’s edge, London South Bank University’s final year students are completing their studies and pondering their futures.

The university has long been a champion of CAD systems, and as its senior lecturer in CAE applications and director of digital prototyping Tony Roberts explains, they have been designing in digital for over 20 years, beginning with MasterCAM V.3.

Although the university and its courses are well stocked with software and prototyping machinery, like many other universities around the country, they don’t have as great a spending power as many imagine.

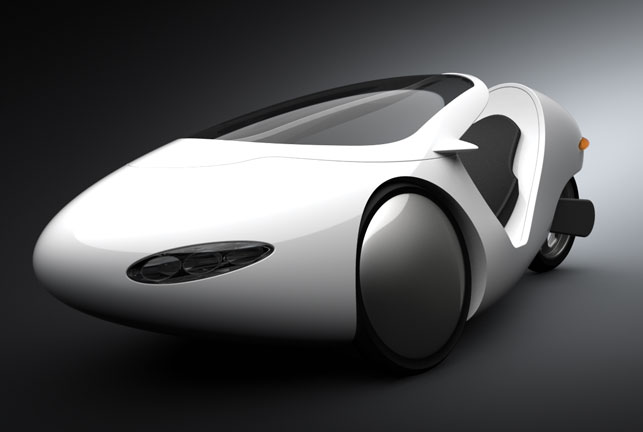

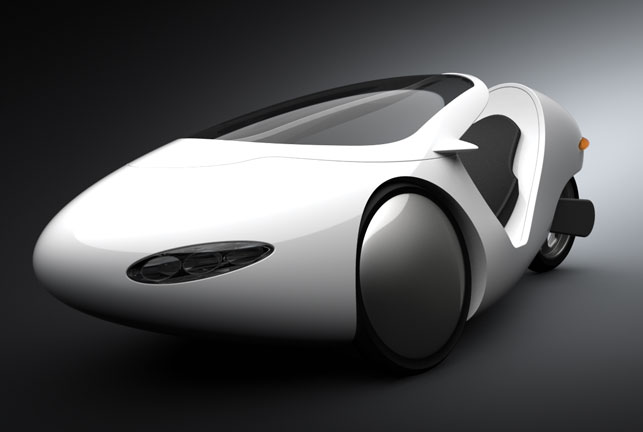

Three-wheeled, concept vehicle designed by Simeon Gentle

With student numbers across the country hitting highs as some people return to education following enforced redundancies, it is interesting to see how a university adjusts, if at all.

A new set of tools and clamping systems for a recently installed Mazak five-axis machining centre is next on the list of additions for the department, yet this proposal like many others is subject to rigorous discussion at senior level to ensure that any funds allocated will add value particularly during such economically sensitive times.

None of the restraints of procuring machinery seem to be impacting on the availability of software for students. The computer aided design course encourages them to cover a wide range of programs, developing and specialising in particular aspects of design for their final year thesis.

The vehicle was part of Simeon’s final year project

“We try to give them a broad understanding of the various technologies used in industry,” says Tony. “In the first year we look at AutoCAD as a 2D system but then very quickly introduce them to the limitations of that approach. We introduce Solid Edge as a 3D modelling system, but only as a part modeller.

“The assembly side of modelling is explored during the second year where we actually start building much more complex systems. NX is used in the final year where students have the opportunity to learn much more about collaborative design and the associated tools available in such ‘high-end’ systems.”

Autodesk’s AutoStudio has been adopted as the main tool for surface modelling, giving the students greater understanding of the differences between that and solid modelling and for working in a particular way when dealing with designs requiring a more flexible approach to surface form.

Outside of the normal lecture periods nothing is set in stone in terms of what students are allowed to use for individual projects, and as the students reel off the various analysis applications they have used they’re keen to point out the hours spent in the workshops as well. “They are encouraged to do physical testing and try to understand why those results can often be different to the answers from analysis software,” adds Tony.

I’ve been taught how to use a variety of different CAD software. I’ve used them to develop concepts into practical models, analyse them and use the data to manufacture using rapid prototyping’’ Simeon Gentle, final year student

The final year projects show the achievements gained by working in different applications. This year’s students are all buzzing over the effects that hyperShot has had on their work compared to other visualisation tools they’ve used.

Tony admits that even though the University has invested in Autodesk’s 3ds Max, ImageStudio and Showcase, and Rhino’s Flamingo products, he is impressed by the students’ tenacity in seeking out other options to gain the optimum results, something that also helps keep the course working with the latest technology available.

The best example of hyperShot being used is in the renderings of final year student Simeon Gentle who, for his final project, has produced a small, three-wheeled, concept vehicle ‘able to meet everyday needs.’ He aims to compare the processes of traditional clay modelling with that of digital prototyping and analyse both for efficiency and constraints.

“I’ve been taught how to use a variety of different CAD software. With these programs I was able to develop concepts into practical models, analyse them to determine feasibility and then using this data manufacture using rapid prototyping or CNC machining.

The students produced renders in HyperShot

“When I graduate my goal is to pursue a job as a design engineer in the automotive industry,” says Simeon. “I’m confident that I have gained the creativity and engineering knowledge to adapt,” he adds before concluding that in a world where graduate jobs are few and far between, he’d gladly return to South Bank for postgraduate study, a choice it seems many will also view as the safer option.

This summer is going to be one full of tough decisions for many graduates. The financial and employment problems won’t be going away for a while yet. Education and training can set you apart from others but not guarantee you a job. However, the versatility of the students at London South Bank University is another weapon in their arsenal. Not tied to a particular software and the ability to work outside the normal methods, they should at least stand a fighting chance in what was already a challenging job sector.

www.lsbu.ac.uk/esbe

How are universities and students being affected by the recession?