Inside the new XJet Additive Manufacturing Centre in Israel

XJet has continued to build on its nano-particle jetting approach to 3D printing, announcing a new ceramic material aimed at the engineering sector and developments on its soluble support material.

Launched as a commercial product only a year ago, its Carmel 1400 system is capable of building parts in ceramics, metals and in the future has the potential to combine the two into a single printed part.

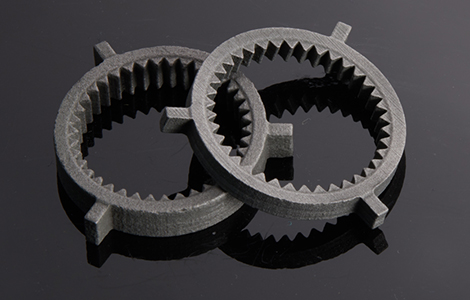

Already producing high-resolution, 99.95% dense ceramic parts from Zirconia, the new ceramic material, Alumina, offers a wider range of engineering uses, faster builds, and more opportunities to manipulate the part while in both its ‘green’ and fired states.

Metal printing on XJet’s platform will become commercial in 2019

It’s an intriguing approach to 3D printing; based on jetting nano-particles of materials much smaller than those of traditional powder bed processes, enabled by suspending them in a liquid (which evaporates in the 300°C build chamber), and building up the layers to form parts.

The updated soluble support materials can now be removed using little more than a water-based solution bath, with any delicate geometry or fine details unlikely to be damaged during the removal process.

The Carmel system is capable of printing parts at resolutions of 3-8 microns for metals and 10-15 microns for zirconia, an astonishingly high resolution when compared to the typical 50 microns per layer for most metals SLS-type methods, or the 50-100 microns of HP’s Metal Jet binder jetting.

The density of parts is likely to attract a lot of interest, and while the figures for its metal parts have not yet been revealed, XJet CEO Hanan Gothait explained to us that the final product is ‘much healthier’ than parts made by other means and more able to simulate accurately, thanks to the isotropic nature of the nano-particle shrinkage.

XJet’s metals 3D printers are set to launch in 2019 with the company saying it is already facing a rush of orders for its current ceramics system, the latest customer being announced as BeamIT, Italy’s largest additive manufacturing centre.

Additional orders also include a second installation for Oerlikon, a leading 3D printing service provider across Europe, based in Switzerland with facilities across Germany.

To keep up with demand XJet has announced that it has upgraded its manufacturing set-up, allowing it to increase output considerably.

Much of the research and development work is taking place at XJet’s new $10M Additive Manufacturing Centre which held its public opening last month in Rehovot, Israel.

One of the largest facilities of its kind in the world, the new 8,000 sq ft R&D centre has 9 Carmel systems running full time for testing, quality assurance and new material and technology development across both ceramics and metals.

With a maximum space for 12 test machines, XJet expects it will fill that capacity rapidly, such is its current state of growth.

Having announced its second funding round (the previous round received funding from venture capital firm Catalyst CEL and Autodesk), XJet has continued to grow its staff to 120 employees, and additionally declared the UK’s Carfulan Group as its first global distribution partner.