In its bid to convince the automotive world to stop bashing out bits of steel and to do something altogether more modern, the 3i-PRINT project has updated an old Volkswagen Caddy to demonstrate the full potential of 3D printing.

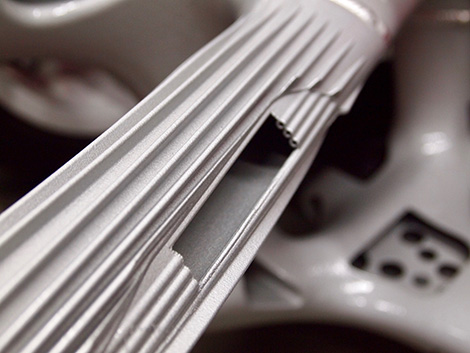

A new front-end structure has been designed and built to be light, stable, and, at the same time feature a high degree of functional integration – billed as the ‘true value proposition of additive manufacturing in automotive engineering’.

The project was undertaken as part of the the 3i-PRINT project, featuring experts from Altair, APWorks, CSI Entwicklungstechnik, EOS, GERG, and Heraeus, with considerations extending far beyond structural mechanics and lightweight construction.

The functional integration, implementing as many technical features as possible with as few components as possible with the resulting added value, is an additional teaser for promoting the use of 3D printing lucrative for the automotive industry.

Stefan Herrmann, responsible for light weight design within the body in white team at csi, said: “The new structure and the contrast between old and new impressively demonstrates the potential that 3D printing and functional integration offer, particularly for the automotive industry,

“I would also like to emphasize the agile, time-efficient route from the initial idea to the fully converted vehicle, which was completed within only 9 months.”

In view of the growing trend towards electrification in the automotive sector, such as the drive train and actuators, heat management as well as the reduction of design space and overall weight were crucial points when designing the front-end section.

Moreover, structural requirements relating to vehicle safety, performance, and comfort needed to be addressed.

Accordingly, parts of the additively manufactured front are load-bearing structures that include details for both active and passive cooling – for example with a channeled airflow to cool batteries and brake systems. In addition, functions linked to heat management, passive safety, and fluids storage have been integrated in the organic, load-driven design of the front-end module.

One example for the integration of additional functions into the structure is the fountain solution tank, which could be integrated into the front end structure when conducting the topology optimisation.

After the successful simulation and design of the concept, APWorks, a subsidiary of Airbus, took care of the final dimensioning of the components for 3D printing using the EOS M 400 system SLS systems.