High extrusion temperatures mean that engineering-grade materials can easily be recycled for future 3D printing

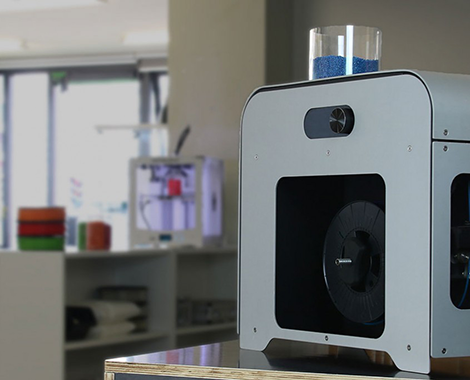

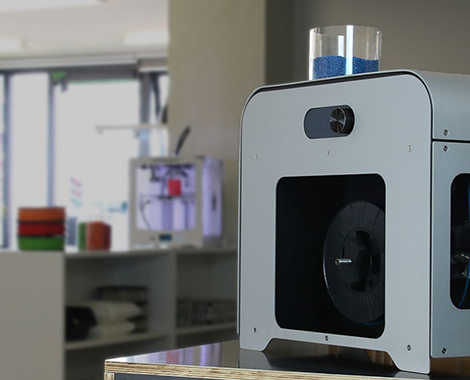

3devo has launched two industrial desktop filament extruders, the 3devo Next 1.0 and 3devo Advanced, as it aims to put high reliability, repeatability and tolerances in a small form factor.

The goal is to allow users to produce 700g of accurate filament per hour – significantly reducing the cost of 3D printing filament (typically around $30-45 per kilo) by using regrind or industrial virgin plastic granulate (typically around $2-8 per kilo) to make their own filaments.

Researchers can also use the 3devo machines to produce small batches of new materials in order to develop new grades or types of filaments.

Cost saving could be huge, given typical reels of filament cost around $45 per Kg, the 3devo extruder claims material costs of under $10 per Kg

Extrusion temperatures of up to 450°C mean you can successfully extrude exotic high temperature engineering plastics, such as PEEK, with the 3devo.

Highly automated, the machines can set an extrusion diameter between: 0.5 – 3.0mm, and has as easy to use spool mount that can variably set for different spools to suit various 3D printers.

The 3devo Next 1.0 costs €3,100 before VAT, while the 3devo Advanced costs €3,950 for the black powder coated variant and €4,150 for anodized variant.