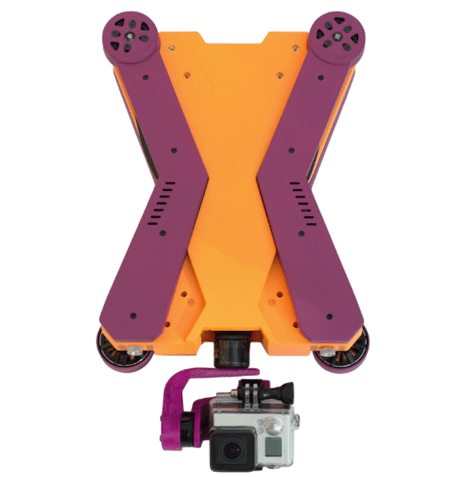

The AirDog, an automated drone that follows a wrist-worn tracking device and can house a GoPro sports camera

For extreme sports lovers, recording the jaw-dropping moment you finally landed that jump (or crashed monumentally into the side of a cliff) is now part and parcel of the thrill.

However, strapping a camera to your head or needing a third party cameraman is not the only option available. Now you can have your own personal aerial tracking shots.

Entirely 3D printed, AirDog is an auto-follow UAV set up to fit your GoPro camera, following you to the limits (or your untimely death), recording everything in HD as it goes.

The 3D printed drone is specifically designed for keeping up with extreme sports, on land, snow or water

UAV start-up company, Helico, has launched the AirDog, an automated drone quad-copter that operates via a wrist-worn tracking device and accommodates a standard GoPro sports camera.

Users can capture their own live aerial video footage and still photography of themselves, having set distance, speed and height levels for AirDog to follow.

“AirDog not only grants end-users their own affordable and personal aerial video crew, but goes one step further in providing thrilling footage from distances and angles previously inaccessible to such consumers,” said Edgars Rozentals, co-founder and CEO of the Latvia-based, Helico Aerospace Industries.

As we’ve covered before, the UAV industry loves 3D printing, with it allowing weight-saving designs, and manufacturing flexibility in a short space of time.

Rozentals previously tried to work with silicon-molded designs through a supplier in China, but as if the two-week turnaround time wasn’t bad enough, the resulting models proved too heavy for take-off.

“The benefits delivered by 3D printing compared to the method we trialled originally are numerous,” says Rozentals.

“Above all, turnaround time is significantly reduced and if we need to make last minute changes to a design, we can do so within a matter of hours, easily and cost-effectively. This was simply unachievable before as it necessitated time-consuming production of a costly new mold.

“I founded the company two years ago and we’re a staff of three, so for start-ups like Helico, this technology isn’t just a game-changer, but the ticket to the game itself,” he explains.

The AirDog even folds away for compact carrying

The final AirDog drone was fully 3D printed using Stratasys’ FDM-based ULTEM material, which offered functional stability, enabling very thin walls that further reduced AirDog’s overall weight.

The accompanying AirLeash wrist-worn tracker was also developed using Stratasys’ PolyJet multi-material 3D printing technology to produce prototypes that combine rigid and rubber-like materials to produce everything from the robust housing case to the soft buttons on the keypad.

https://www.kickstarter.com/projects/airdog/airdog-worlds-first-auto-follow-action-sports-dron/widget/video.html