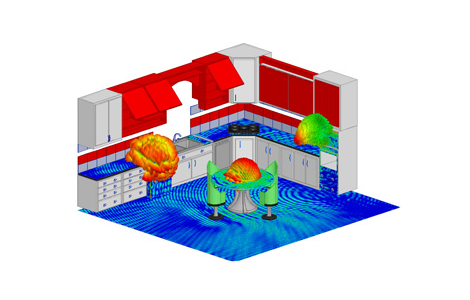

Ansys 16 offers the ability to prepare designs for the Internet of Things through serious simulation work – including electromagnetic disturbances like in this humble domestic kitchen

From simulating software and hardware interactions for the Internet of Things, to better understanding the full spectrum of structural materials, Ansys is setting the bar high with its latest release.

Release 16 is aiming to enable users to validate complete virtual prototypes of complex systems to address all the emerging engineering challenges – it’s a big task, but it has some incredible tools to make it happen.

Its headline grabbers are clearly in an area Ansys feels it can swiftly move into – enabling connected electronic devices – or its better known buzz term, Internet of Things (IoT).

Ansys believes that the increased levels of connectivity are needed to allow the IoT to truly prosper requires a higher standard for hardware and software reliability.

As part of the new release, it now has capabilities to verify electronics reliability and performance throughout the design process and complex electronics industry supply chains.

The biggest introduction it the Ansys Electronics Desktop, a single-window, integrated interface that brings electromagnetic, circuit and systems analysis into a single working environment to simplify the process and help ensure users are following simulation best practices.

The ability to create 3D components and integrate them into larger electronic assemblies allows for the creation of wireless communication systems, especially useful as systems become more and more complex.

Simulation-ready 3D components are created and stored in library files that can be added to larger system designs without the need to apply excitations, boundary conditions and material properties.

Ansys 16 aims to be able to simulate the most structural materials yet as an aid to designers looking to reduce product weights while improving structural performance and design aesthetics.

Sheet metal and plate steel are common traditional material forms used to minimise weight while delivering required structural performance, with Ansys 16 accelerating the process for engineers to model these thin materials and define how parts are connected in a complete assembly.

Within the aeronautics domain, this release has upped it safety requirements – providing a model-based approach that satisfies the requirements of DO-330, the tools qualification document within DO-178C.

DO-178C, Software Considerations in Airborne Systems and Equipment Certification, is the new document that such authorities as the Federal Aviation Administration and the European Aviation safety Agency will use to approve all commercial software-based aerospace systems, and Ansys 16 is the first tool to meet that new certification requirement.

New functionality for composite designs and comprehensive tools for understanding the solution results are another improvement, looking to tackle the usual problems of their non-homogeneous properties and their dependence on the manufacturing process.

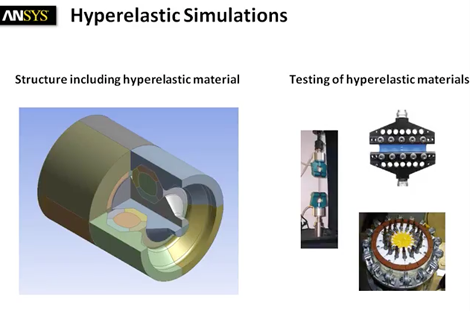

Ansys 16 features advanced simulation solutions for elastomers like rubber

Elsewhere, advanced simulation solutions for elastomers like rubber, feature adaptive remeshing, which refines the mesh in highly distorted areas without the need for the user to stop the simulation manually.

Contact simulation between multiple parts has also seen advancements in Ansys 16, some of the most challenging simulations for structural analysis, especially with the expansion beyond traditional engineering material.

The contact improvements include a combination of better contact management and the new visualisation and customisation tools, which should help for better engineering simulations.

For complex fluid dynamics challenges that lead to engineers having to study more complex designs and physical phenomena with less time, Ansys is looking to reduce its preprocessing time by up to 40 per cent.

That’s a big chunk of time, and is probably helped along by this release takes full advantage of Intel Xeon processors and Intel Xeon Phi co-processors to bring new levels of performance to Ansys simulations.

This release further reduces the time for optimising design changes by leveraging the adjoint optimisation technology and making it more practical for engineers to use.

A new adjoint designer tool enables engineers to perform multi-objective shape optimisation, including constraints. They can now use the adjoint solver and model up to a whopping 50 million cells.

As part of the launch for Ansys 16, it is introducing Ansys AIM, an immersive simulation environment that lowers the barrier to entry for multiphysics simulations.

‘AIM simulation uses Ansys technology packaged in a new environment, accessible to the entire engineering organization’ is the vague news we have already, but expect a guided simulation process with high levels of automation.