Do forgive me for this, I didn’t get the chance to get this posted while out in Korea, so here’s the second day of the event’s thoughts and ponderings:

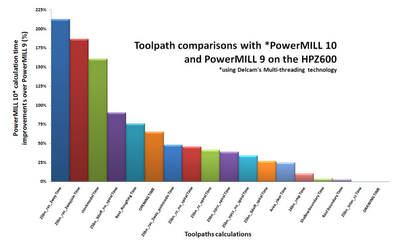

After an evening spent with some wonderful company in a traditional Korean resturant, the first day was all about 3D design and development tools, the second day of the Tech Summit is all about manufacturing and production, starting with PowerMill 10. This is the first of two releases this year, with PowerMill 2010 coming later on. The reason for this is that Delcam has added two key technologies that it’s customers have been crying out for. The first is multicore support has been added into PowerMill 10. This will split a tool-path into segments (according to the number of cores you have) and calculate one of each core. As with many things, some processes are more suited to parallel processing than others. In the world of CAM, it’s most useful when you’re using raster tool-paths. The good news is that many of PowerMill’s functions are raster based. The other operation or process type that gets real benefit from this is stock calculation, where the model is processed after each tool-path’s creation to maintain an accurate model of the remaining material.

Alongside this, release 10 also gets background processing capabilities. In the current release, you define your tool-path, then calculate it. This locks up PowerMill while the chunking is done. From the release 10 onwards, you can set-up tool-paths, add them to a queue, then continue to work on your part, adding more operations to the queue while your machine is calculating the tool-paths in the background.

Where the benefits can be gained with multi-threading support

It’s important to note two things, the background processing does not require multi-core workstations. The other relates to working on multiple jobs at one time. As default, PowerMill allows two sessions. In previous releases, this allowed you to open two jobs you’re working on and run them both in parallel. But the background processing tool uses one of those session licenses. So, while you can queue up multiple calculation tasks, you’re not going to be able to run two sessions without an additional license. If you have networked flex licenses, this shouldn’t be a problem, but if you’re running a standalone workstation and often use two sessions, you might run into difficulties.

PowerMill 2010

While these new tools are going to the PowerMill 10 release, Delcam aren’t done for PowerMill for this year. PowerMil 2010 will be another major release later this year, with redesigned forms and dlalogs giving you access to operation variables in a much quicker way without switching dialogs. There will be new roughing operations that will avoid thiun slithers of material, which is something those of you using insert-based cutter will know is a problem (the slithers can rip the inserts straight out and these things ain’t cheap). Corner Clearance when roughing is going to be improved and will removes materials left in corners in successive layers – it’s similar to trochoidial roughing, but works across more operations.

The last two major updates are a new smoothing algorithm which can be applied across a whole toolpath, adding arcs across all areas of a toolpath to create a seemless toolpath – previously, the addition of arc was reserved for corners – and should give you a much better surface finish. Finally, the new Tool Holder Profile tools can help you to find the most appropriate toolholder for your machining task. This is done by finding the minimum profile that can safely fit into every area of the part across all of the tool-paths. It then gives you that information when you’re working on tool holder selection(by means of a graphical representation), allowing you to find the best holder for the job and to make adjustments to other settings (such as overhang) to get the best results.

Oh and there’s also new tools for assist with collision avoidance in 5 axis operations. While it’s not a new feature per-se, it’s been optimised to give you a much smoother tool-path and machine movement (previous releases could give you quite harsh machine movements).

Delcam PartMaker

This is another company that Delcam acquired a few years ago. PartMaker is predominately used to program both swiss lathes and turn mill applications. For those unfamiliar with Swiss Lathes, they’re typically used to create smaller parts using sliding stock and multiple spindles. The combination of constant feed and moving material and the multiple spindles means that you can highly compress and optimise your operations (synchronising between the two machining spindles) and build parts at a very high rate.

Of course, the programming software is essential, because if you can shave fractions of seconds out of a single part, then when you multiply that by part volumes (we’re talking 100,000+ units), even the most modest of time savings can quickly stack up to greater productivity. Also, the complex nature of these types of machines, particularly when you consider some have 11 or more axis of movement, means you need some bullet proof coding tools.

Updates for this release are the introduction of 5 axis operations. There’s also greater integration with PowerMill, allowing you to switch data from PartMaker to PowerMill to work on very complex operations, then integrate those operations back in PartMaker. While the origins of the Swiss lathe lies in the Swiss watch making industry, the machines have been adopted across many industries sectors, from aerospace to medical, so while the term lathe may give you an impression of axisymmetric parts, almost anything can be machined as long as it can fit within the bar size.

FeatureCAM

FeatureCAM is another of Delcam’s recently acquisition that’s become more integrated into the product portfolio. Alongside PowerMill and PartMaker, it may seem redundant that Delcam has another part programming tool, but each has it’s own areas of speciality and concentration – and as such, there’s different language and terminology for each. To give you an idea of what FeatureCAM is about is about firstly formalising your knowledge and best practice in terms of machining operations variables (speeds, feeds, step-over etc), cutter preferences and such. It’s then about providing a knowledge-based environment in which you can generate part programs very quickly indeed. It does this by recognising features within your parts (as such, it’s inherently most suited to prismatic parts) then generating operations to create those features. The feature-based nature of the system also gives a better environment for CAD/CAM integration, as the system can reload updated geometry, find which boundaries have changes, which features have shifted, been added or removed, then update the program accordingly.

Where the benefits can be gained with multi-threading support

It’s important to note two things, the background processing does not require multi-core workstations. The other relates to working on multiple jobs at one time. As default, PowerMill allows two sessions. In previous releases, this allowed you to open two jobs you’re working on and run them both in parallel. But the background processing tool uses one of those session licenses. So, while you can queue up multiple calculation tasks, you’re not going to be able to run two sessions without an additional license. If you have networked flex licenses, this shouldn’t be a problem, but if you’re running a standalone workstation and often use two sessions, you might run into difficulties.

PowerMill 2010

While these new tools are going to the PowerMill 10 release, Delcam aren’t done for PowerMill for this year. PowerMil 2010 will be another major release later this year, with redesigned forms and dlalogs giving you access to operation variables in a much quicker way without switching dialogs. There will be new roughing operations that will avoid thiun slithers of material, which is something those of you using insert-based cutter will know is a problem (the slithers can rip the inserts straight out and these things ain’t cheap). Corner Clearance when roughing is going to be improved and will removes materials left in corners in successive layers – it’s similar to trochoidial roughing, but works across more operations.

The last two major updates are a new smoothing algorithm which can be applied across a whole toolpath, adding arcs across all areas of a toolpath to create a seemless toolpath – previously, the addition of arc was reserved for corners – and should give you a much better surface finish. Finally, the new Tool Holder Profile tools can help you to find the most appropriate toolholder for your machining task. This is done by finding the minimum profile that can safely fit into every area of the part across all of the tool-paths. It then gives you that information when you’re working on tool holder selection(by means of a graphical representation), allowing you to find the best holder for the job and to make adjustments to other settings (such as overhang) to get the best results.

Oh and there’s also new tools for assist with collision avoidance in 5 axis operations. While it’s not a new feature per-se, it’s been optimised to give you a much smoother tool-path and machine movement (previous releases could give you quite harsh machine movements).

Delcam PartMaker

This is another company that Delcam acquired a few years ago. PartMaker is predominately used to program both swiss lathes and turn mill applications. For those unfamiliar with Swiss Lathes, they’re typically used to create smaller parts using sliding stock and multiple spindles. The combination of constant feed and moving material and the multiple spindles means that you can highly compress and optimise your operations (synchronising between the two machining spindles) and build parts at a very high rate.

Of course, the programming software is essential, because if you can shave fractions of seconds out of a single part, then when you multiply that by part volumes (we’re talking 100,000+ units), even the most modest of time savings can quickly stack up to greater productivity. Also, the complex nature of these types of machines, particularly when you consider some have 11 or more axis of movement, means you need some bullet proof coding tools.

Updates for this release are the introduction of 5 axis operations. There’s also greater integration with PowerMill, allowing you to switch data from PartMaker to PowerMill to work on very complex operations, then integrate those operations back in PartMaker. While the origins of the Swiss lathe lies in the Swiss watch making industry, the machines have been adopted across many industries sectors, from aerospace to medical, so while the term lathe may give you an impression of axisymmetric parts, almost anything can be machined as long as it can fit within the bar size.

FeatureCAM

FeatureCAM is another of Delcam’s recently acquisition that’s become more integrated into the product portfolio. Alongside PowerMill and PartMaker, it may seem redundant that Delcam has another part programming tool, but each has it’s own areas of speciality and concentration – and as such, there’s different language and terminology for each. To give you an idea of what FeatureCAM is about is about firstly formalising your knowledge and best practice in terms of machining operations variables (speeds, feeds, step-over etc), cutter preferences and such. It’s then about providing a knowledge-based environment in which you can generate part programs very quickly indeed. It does this by recognising features within your parts (as such, it’s inherently most suited to prismatic parts) then generating operations to create those features. The feature-based nature of the system also gives a better environment for CAD/CAM integration, as the system can reload updated geometry, find which boundaries have changes, which features have shifted, been added or removed, then update the program accordingly.

Point of thought

The past two days brought home something I’ve been thinking about for a while and that’s the CAM industry in general. While there’s an increasingly degree of consolidation (something that’s only going to increase), it’s still a highly fragmented industry, both in terms of geography and in terms of functionality. While the geographic fragmentation isn’t going to change much until the larger vendors start to swallow up the smaller vendors out there and others disappear. Obviously there’s an economic crisis which might see smaller CAM vendors get into trouble and sell out before it’s too late, but there’s also an age issue. Quite a number of CAM vendors are privately owned by the person or people that started them in the late 70s and 80s. Many of these people are getting towards retirement age and you’ll see greater consolidation due to that reason alone.

In terms of functionality fragmentation, this is also something that’s inevitable. Within the world of CAM, there are many processes, many machine types and many different variables, meaning that the proliferation of systems is natural. The type of machine tool you run often filters out your list of software available, particularly if you choose not to go with your machine tool vendor’s recommendations. While if you’re running a 5 axis machine tool, you have a wide selection, when it comes to systems such as the more complex mill/turn or swiss lathe type machines, the list isn’t as quite as extensive.

Also consider your company’s requirements and where you need to place the priority for your CAM work. Are you looking for the greatest surface finish on a highly complex part, are you looking to create high volumes of parts using a mill/turn where reduction of part cycle time is key or are you looking at quick turn around one offs or small volumes with minimum machine set-up time, where part programming needs to be quick.

What’s interesting is it’s a rare occasion indeed when you’d find tools to support all these options and requirements from a single vendor. While Delcam’s name was built within the world of mould and die design and machining, the last 10 years have seen the company hugely expand its offering, both in terms of a wider spread of CAM-variants, but also in terms of new processes, both upstream and downstream. The solution set now covers everything, from conceptualisation and design, through tooling design, NC programming right through to inspection. you’re now seeing greater integration between all of the systems and cross pollination of technology between the various constituent systems. PowerShape gets mesh handling tools from CopyCAD, PartMaker now swaps data with PowerMill etc etc etc. It’s highly impressive and something that many other vendors could learn a thing or two from.