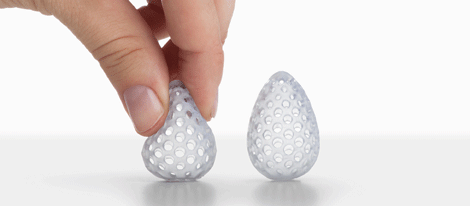

The new cartable resin should burn out cleanly, without ash or residue, capturing crisp, precise details, and smooth surfaces

FormLabs has announced a new family of high-performance functional resins, allowing for the production of castable and flexible parts.

The new resins for the desktop Form 1+ SLA 3D Printer allows for the investment casting of metal parts, as well as the printing of soft, impact-resistant models.

The castable resin is designed to hold fine detail and burn out cleanly, a requirement for investment casting, making it ideal for jewellery, metalwork, and engineering applications.

Flexible is a rubber-like material, ideal for hinges, engineering applications, shock absorption, tactile surfaces, and other applications requiring resilient, pliable parts

The flexible resin is a rubber-like material that’s pliable when thin and resilient when thick. It’s ideal for applications requiring a soft feel or impact resistance.

“Much of the attention in 3D printing is focused on the machine,” said Formlabs co-founder, Maxim Lobovsky. “At Formlabs, we’ve always considered the materials to be just as important. A library of functional materials has always been part of our plan, we’re pleased to introduce these resins to the world.”

With a growing team of material scientists, Formlabs is looking to create a comprehensive, high-performance suite of resins for its 3D printers.

“Diverse materials are such a key piece in enabling innovation,” said Formlabs’ material scientist Katherine Hammes. “We’ve formulated our new resins to work seamlessly with our machine, and we’re thrilled with the results we’ve achieved with Castable and Flexible.”

The castable resin is available in 500ml bottles from the Formlabs web store immediately, while customers will have to wait till December to try out the flexible product. Both resins are compatible with both the Form 1 and Form 1+ 3D Printers.

Read our review of the FormLabs Form 1+ here.