AI technology looks set to impact every aspect of product development: dreaming up concepts, building parts, and optimising and automating the way they are manufactured. With new AI-enhanced tools being launched now on a regular basis, and their forerunners rapidly improving in leaps and bounds thanks to increased training, this is a fast-moving trend that leaves many prospective customers struggling to keep up. To bring you up to speed, we’ve picked out a few notable companies working in some of the key sectors

Text-to-CAD 3D generation

While text-to-image technology is already widespread and popular in 2D work, 3D parametric models present a trickier challenge. That said, start-ups specialising in professional tools for building physical products are able to make some impressive boasts about their capabilities.

The idea is straightforward enough: the user enters as much information about the desired end result as they can succinctly describe. What they get back is a 3D model of a part that can be edited further or exported to your CAD package.

Adam

Adam is the newest tool on this list, but only by a matter of days, such is the speed at which this market moves. Its USP is that it offers a more conversational platform than competitors, with a text-to-CAD interface that feels more like firing messages to a customer service chatbot than simply typing into the void. Sliders are a big help in controlling measurements, such as setting a wall thickness or a corner radius, for example. From there, parts can be exported straight to 3D printing or pushed into CAD. Adam is a member of Y Combinator’s Winter 2025 cohort, and looks set to benefit from its involvement with the start-up accelerator, which is backed by the VC firm behind Airbnb, Dropbox, Twitch and many more.

Backflip

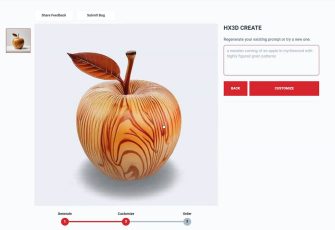

Taking in user input text prompts or images, Backflip then generates multiple designs as high-res renders, before allowing users to edit further and generate a 3D model that can be exported as an STL or OBJ file. Backflip’s development continues to be rapid, with its founders, the team behind 3D printer company Markforged, looking to build the ultimate design tool for creating ‘real things’ and having ambitious plans to link their technology to existing CAD tools, parts catalogues and more.

Zoo AI

The Zoo Text-to-CAD modeller generates B-rep surfaces, enabling 3D models to be imported to and edited in any existing CAD software as STEP files. That’s a contrast from other text-to-3D examples that generate meshes – which, once imported, can’t always be edited in a useful manner. Much of Zoo’s achievement is down to its hard work on the infrastructure behind Textto- CAD, which uses its own proprietary Geometry Engine, Design API and Machine Learning API to analyse training data and generate CAD files. The capability for a CAD model to be edited naturally makes generated models far more useful.

HP AI3D

HP’s AI3D Design Services software – internally named 3D Foundry – has come along just when the 3D printing mainstay is looking to unlock new AM applications. This simple toolset uses text-to-CAD to generate a design, a 3D lattice and then export it to 3D print using HP technology. HP executives have been keen to explain that they see businesses using the tools to support product customisation. While professional designers would design the key elements of a product in order to comply with standards and regulations, customers could contribute to other design elements, such as the lampshade on a light fitting.

Machining

With the manufacturing sector rarely out of the headlines, securing the future of how parts, moulds and dies are built is important.

Compared to today’s often error-prone, time-consuming and expensive process, which typically relies on expert manual programming, an automated approach driven by AI and machine learning could be a massive win for product development. By making precision manufacturing more autonomous, it’s hoped that businesses will see an improvement in the ease, speed and reliability with which parts are made. That, in turn, could lead to improved costs, resulting in more manufacturing getting reshored and supply chains becoming more local.

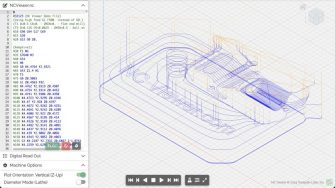

CloudNC – CAM Assist

Single-click manufacturing is still be some way off for more complex designs, but CloudNC is making bold steps with CAM Assist, especially in 3-axis machining. This is available as a plug-in for Autodesk Fusion, Mastercam, Siemens NX CAM and Solid Edge CAM Pro. Once you’ve opened your CAD model and added in your tool library, machine, stock material and machining mode (3-axis or 3+2), CAM Assist creates the machining strategies, feeds and tool speeds. You then export the G-code and manufacture the part on your machine. CloudNC executives claim that its software takes users 80% of the way. Its ability to balance cycle time, surface finish and tool make it an impressive piece of technology.

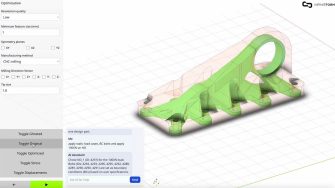

InfinitForm

InfinitForm aims to increase the manufacturability of a design long before any metal gets cut, by offering tailored design constraints for parts in relation to the manufacturing processes you have available. Built by the founder of generative design tool ParaMatters, which focused on topologyoptimised designs for 3D printing, InfinitForm creates optimal, machine-friendly prismatic models from the design stage onwards. The software imports CAD and acts as an AI co-pilot during design stages, taking in the material and tool constraints upfront, leading to reduced cycle times and minimal post-processing requirements.

Toolpath

Another tool for 3-axis machining that integrates seamlessly with Autodesk Fusion’s manufacturing workspace, Toolpath uses AI to help automate time-consuming tasks like design-for-machinability analysis, quoting and CAM programming. Its ability to analyse parts, estimate costs and create a machining strategy aims to reduce bottlenecks and reduce repetitive tasks, freeing up the time and talents of machinists to tackle more complex problems. To help those machinists, Toolpath has constructed a guide that it says can teach anyone to use the plug-in in just 30 minutes.

Additive Manufacturing

The complexities associated with additive manufacturing (AM) come to a head at the build preparation stage.

The specific requirements of every process, machine and material mean that getting this right (let alone optimised) can be a tough challenge. Expensive failures are too often the end result. But AI can deliver better parts, more complicated builds and fewer errors through its ability to optimise build supports, proactively predict failures and more. Some tools are even able to correct errors ‘on the fly’, increasing print yields and pushing AM further in the direction of mass manufacturing.

1000Kelvin AMaize 2.0

The second release of AMaize offers automated design printability checkers, optimised build preparation and intelligent adjustments to scan strategies and process parameters. By populating its Virtual Shop Floor with all the machines and materials you have, the software can suggest strategies that increase productivity and reduce print fails. AMaize’s tools for printability check the design before it heads to production and help identify distortions, overheating and shrinkage. A physics-based approach means that during build prep, AI generates support structures only where necessary, reducing material usage as well as the time it would take an experienced operator to manually add those structures.

AI Build

If you’re printing big parts, then AI Build may be for you. A hybrid platform for robotic and LFAM 3D printing, it combines AM with tailor-made CNC strategies, all through the same user interface. Different parts will require different slicers to put down material layers and create toolpaths for a build. AI Build can assist with all that, before enabling you to package your process into a ‘recipe’ that can be used again and again. Many tasks can be carried out using the AI co-pilot, which makes recommendations and off ers smart setting defaults. Upgrades beyond the standard version include build process monitoring and defect detection. AI Build is available either on the cloud or on-premise for added off -grid security.

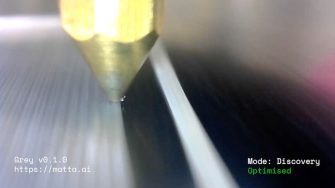

Matta – Grey 1

Founded at the University of Cambridge by a team of AI and manufacturing engineers, London-based Matta is looking to improve build quality, increase 3D print yields and help automate the factory of the future. Equipped with advanced error detection, parameter prediction and optimisation capabilities, its Grey software learns from every print produced within its global network of 3D printers. Its initial toolset in Grey 1 is more machine learning than AI, but off ers an exciting indicator for where the tech is heading. Able to correct errors on the fl y, it can ensure quality prints fi rst time, reducing failure rates and making AM more applicable to volume production. The software creates digital twins of printed parts using G-code, projecting quality measurements onto each extruded line, ready for inspection.

Visualisation

Slick visualisation tools have always been important in product development. But AI’s impact in this area looks likely to be utterly game-changing: stacks of realistic renderings, delivered as early as the concepting stage, which use for reference only quick sketches, a handful of prompts and mere seconds of processing time.

In a world that demands new ideas faster than ever before, generating concepts using generative AI software is fast becoming a norm, far overtaking the compilation of mood boards and lookbooks. AI enables designers to explore multiple ideas, materials and colourways. The better tools offer intuitive control of edits, even allowing you to train the AI on your own design history and maintaining design language as you hit generate. It’s not all about ideation, either; these tools work brilliantly for those who might not be the best sketchers, or for anyone wanting to bring a last-second idea to life in a client meeting.

Krea AI

Krea is not a single software, but an AI platform designed to support a wide range of visual content. Its tools span a whole array of professions, but there are some interesting options in there for product designers. Like other generative platforms, Krea allows users to upload sketches and generate renders, but its wider toolset includes features like Realtime, which enables you to turn 2D images of objects into 3D assets, or take XR sculpting tools and use the output to build detailed concepts. It might take a while to master everything that Krea has to offer, but going on what the product’s online user community is achieving, it can clearly unleash a whole world of creativity.

NewArc

Having recently taken more of a focus towards soft goods, footwear and fashion, NewArc is still an excellent tool for generating and editing product images. A simple sketch and some loose prompts can produce incredibly detailed renderings with realistic lighting across materials.

The user interface is designed without particular skills in mind, so you don’t have to have created even a single product rendering in the past in order to be able to jump straight into what this tool can offer. Among its array of preconfigured styles, it even has a clay rendering mode for traditionalists. All paid accounts come with full privacy included, so that all of your sketches, prompts and images remain solely yours and can only be accessed from your personal account.

PromeAI

Prome is a slightly more straightforward generative AI tool than many others. You enter a sketch, generate a rendering, and then expand it with prompts to adjust CMF and even produce short video clips. This is not to say it’s short of functions, as it has a fully stocked list of AI tools for crafting the perfect image, including AI background generation, and some with particular focus for tweaking the scene lighting. Since realistic, physics-based lighting is something that is often lacking in AI-generated content, any user who knows their way around photorealistic rendering software will appreciate the extra levels of control that Prome offers.

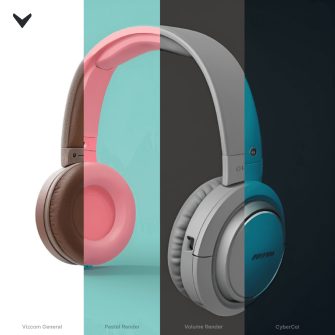

Vizcom

Vizcom is now a feature of seemingly every automotive studio’s software arsenal and offers designers an increased level of control over the sketch and edit workflow. The simple user interface lets users decide how much of their original sketch will influence the overall look, while a library of render styles can be selected, from soft pastels to eye-popping brights.

It’s very clear that Vizcom has been designed by a team steeped in product design, with two features standing out: first, its Palettes feature, which allows users to train its AI with their own design language by uploading up to 30 example images; and second, Workbench, an infinite whiteboard where teams can collaborate, explore and elaborate on ideas.

Simulation

AI is unlocking the upper echelons of what modern simulation software can achieve.

Often, it’s doing so by speeding up the process, automating simulation setups down to a single click in place of hours of manual preparation. Or, it’s delivering improvements by analysing huge amounts of data to highlight the points of a simulation that most matter. Along the way, it’s opening up simulation tools to more engineers, enabling them to perform rigorous testing earlier on in the design workfl ow, so that experts need only inspect the higher-level details.

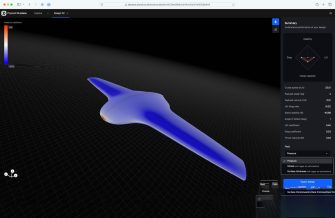

Luminary

Luminary is a simulation-as-a-service, high-fidelity CFD solver that relies on cloud-based compute power and makes the CAE workflow faster and easier, thanks to its Lumi AI co-pilot. Lumi AI reduces the time that engineers need to spend on simulation set-up, so that they can instead prioritise analysing results and optimising designs. Part of this toolset includes the Lumi Mesh Adaptation, which automatically generates physics-informed meshes for fast and accurate results that learn from existing solutions. Users can also take advantage of a minimal initial mesh generation feature, which reduces the mesh size required in order to achieve a target level of accuracy. Ultimately, that means a more cost-eff ective, faster simulation.

Monolith

Monolith’s goal is to get 100,000 engineers using its AI tools to cut their product development cycles in half by 2025. It’s a bold target for any start-up to set, but the company insists it is confi dent in its no-code AI approach and machine learning tools that can be used to build pipelines and interactive ‘notebooks’ for loading, exploring and transforming data for AI. Refined from hundreds of AI projects to find hidden errors, streamline test plans and build better products using users’ own historic data, Monolith’s tools allow for the testing and simulation of materials, component design simulations and manufacturability, using past data to help companies streamline their processes and focus on the most impactful areas.

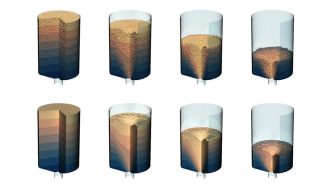

NXAI

With its AI4Simulation toolset, NXAI offers particlebased simulations for modelling multi-fluid systems and fluid-material interactions. AI4Simulation’s fi rst simulation project, NeuralDEM, is an end-to-end, deep learning alternative for modifying industrial processes such as fluidised bed reactors or silos. Aimed at scaling industrial and manufacturing processes, NeuralDEM captures physics over extended time frames. With deep learning, AI4Simulation looks to scale to millions of particles, but has an eye on the future, involving scales that surpass human understanding.

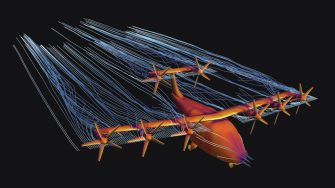

PhysicsX

PhysicsX claims that, once set up, its tools can simulate complex systems in seconds, automatically iterating through millions of designs to optimise performance while respecting manufacturing and other constraints. Any engineer can drive all parts of the workfl ow, even those parts traditionally managed by dedicated experts, with AI automating the most time-consuming tasks, minimising handovers and accelerating iterations. PhysicsX LGM-Aero is a geometry and physics model that has been pre-trained on more than 25 million meshes, representing more than 10 billion vertices, as well as a corpus of tens of thousands of CFD and FEA simulations generated using Siemens Simcenter STAR-CCM+ and Nastran software.

This article first appeared in DEVELOP3D Magazine

DEVELOP3D is a publication dedicated to product design + development, from concept to manufacture and the technologies behind it all.

To receive the physical publication or digital issue free, as well as exclusive news and offers, subscribe to DEVELOP3D Magazine here