Its creators believe that rapid liquid printing, can help reimagine manufacturing as an ‘artistic experience’

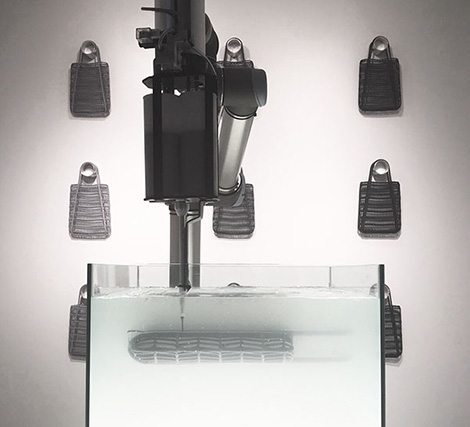

MIT’s Self-Assembly Lab has given insight into the development of its Rapid Liquid Printing technology with the launch of a new ‘futuristic manufacturing facility’ public installation at New York’s Patrick Parrish Gallery.

The 3D printing technology, developed in collaboration with furniture makers Steelcase, uses a tank of gel to suspend the part being printed, which it claims allows for large parts to be produced with better surface quality.

“Rapid liquid printing can produce large-scale objects out of high-grade materials like rubber, foam, or plastic in a matter of seconds or minutes by “drawing” them in a gel suspension,” said a Self-Assembly Lab spokesperson.

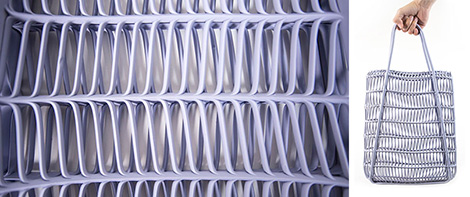

A tote bag from the installation

“With rapid liquid printing, manufacturing can be reimagined as an artistic experience unlimited by scale or gravity, asking us to rethink design, production, uniformity, and product life-cycles.”

The gallery space serves as a manufacturing facility in which a robot instantly prints tote bags and art objects, designed by Swiss designer Christophe Guberan.

After printing, each product is removed, cleaned, and put on display – which doubles as a gift shop

A ‘stretchable light’ created with Rapid Liquid Printing is also on display – its ‘skin’ printed within an 18” cubic tank, suspended within the gel, then removed and washed with water.

A Christophe Guberan 3D printed table light

The printed silicon rubber, a material that would be nearly impossible to produce with any other printing technology, allows the skin to be stretched around a light tube or any other structure, making an object that is far larger than its original print volume.

The stretchability of the material minimizes the size and duration of printing while also creating a minimal storage/shipping volume that can also be customised to create different sizes or geometries by stretching it around different internal frames – lending itself to the possibility of 3D printing inflatable parts.

In 2013 we visited MIT’s Self Assembly Lab to talk about its vision of 4D printing and programmable materials.