Laser melting is a pioneering process capable of producing fully dense metal parts direct from 3D CAD, which has the power to unlock the potential for additive manufacturing.

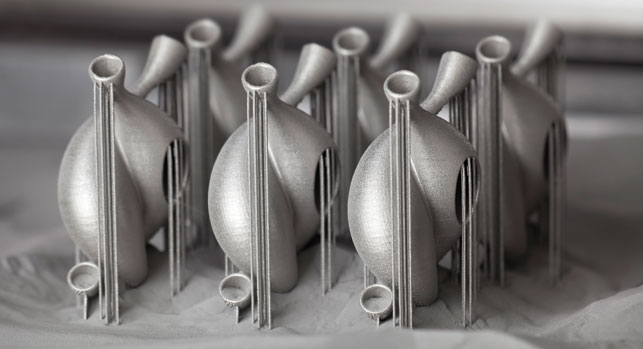

Jewellery at the end of the additive manufacturing build

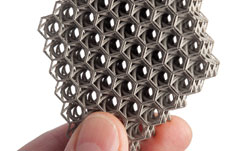

At the core of the process is the use of focused laser energy to fuse fine metallic powders to form highly complex components.

The metallic powder is distributed evenly across the build plate in layer thicknesses ranging from 20 to 100 microns forming the 2D cross section.

The layer of powder is then fused using the laser in a tightly controlled atmosphere. The process is repeated, building up parts of complex geometries, layer by layer.

The technology is already widely employed for the manufacture of custom medical implants, lightweight aerospace and motorsports parts, efficient heat exchangers, injection moulding inserts with conformal cooling channels, and dental copings and crowns.

Laser melting gives designers more freedom, resulting in structure and shapes that would otherwise be constrained by conventional processes or the tooling requirements of volume production, enabling them to rethink the concept of ‘design for manufacture’.

The capability to safely process reactive materials such as titanium and aluminium is a standard feature on all Renishaw machines, with safe systems for process emissions and powder handling. Other materials currently supported include certain grades of stainless steel, tool steel, cobalt-chrome and inconel.

Laser melting users benefit from reduced lead times, tooling costs and minimal waste product, as over 95 per cent of the material is re-usable after refinement in the Renishaw powder conditioning system. It is also complementary to conventional machining technologies.

Process in use

Recent adopters of the Renishaw technology include Swansea University, one of the UK’s top research universities, and Directed Manufacturing Inc. (DMI), a leading US provider of additive manufacturing services. Both organisations have acquired a Renishaw AM250 laser melting machine.

At Swansea University the system is being used by a new ‘Aerospace & Manufacturing’ multidisciplinary research team within the University’s College of Engineering.

Part of the team’s focus is the ASTUTE (Advanced Sustainable Manufacturing Technologies) project, which targets the aerospace, automotive and high technology sectors and aims to create sustainable, higher value goods.

By applying Advanced Engineering techniques, such as additive manufacturing, to both the design of products and to the production process, the project aims ultimately to create new skilled jobs in the manufacturing sector in Wales.

Heavy metal

At DMI a AM250 laser melting machine was purchased to augment an existing range of machines at its engineering facility in Texas, USA, where the company supplies production metal parts and complex geometric components to the medical, industrial, aerospace and defence industries.

The machine has been sourced to respond to the demand from design engineers needing to reduce production lead times and costs.

The Renishaw AM250 is particularly advantageous to DMI because of its large build chamber, allowing the construction of parts up to 250 x 250 x 360 mm in size, but also because of the vast range of metal powders that can be used in part construction.

Alex Fima, DMI CEO explains, “We thoroughly researched our options and selected the Renishaw AM250 due to its reputation for building precision Titanium prototypes and parts.”

Simon Scott, director of Renishaw’s additive manufacturing products division says, “These sales further reinforce Renishaw’s growing reputation as a credible supplier within the additive manufacturing market.

There is great potential for additive technologies to improve energy efficiency and product performance, which is being advanced by the work of pioneering organisations such as Swansea University and DMI.”

renishaw.com

Unlocking the power of additive manufacturing with laser melting

Default