The Formlabs Fuse 1 3D printer, its first to use selective laser sintering (SLS) and a device which the team began working on around 7 years ago and announced in 2017, has finally launched.

This is the first time that Formlabs has stepped away from its traditional stereolithography based machines.

While this is certainly not the first time that a vendor has attempted to build a benchtop focussed laser sinterer, it’s certainly the first time from an established machine builder.

The Fuse 1 launches with a nylon 12 material that promises a 70% refresh rate. This means that you need to add 30% fresh powder to that which has already been used – a pretty solid improvement on the industry standard 50%.

The build chamber is 165 x 165 x 320 mm and modular in nature, meaning the build can be removed and cooled/broken out, while a new one is inserted, heated and built on.

“The Form 1 redefined stereolithography (SLA) printing for the additive manufacturing industry 10 years ago, and now the Fuse 1 is bringing the same reliability and accessibility standard that Formlabs customers expect of industrial 3D printing,” said Formlabs CEO Max Lobovsky.

“SLS 3D printing shouldn’t be solely for those with big budgets, it needs to be accessible so all companies — from startup to big manufacturer — can benefit from the design freedom and high productivity SLS 3D printing provides.”

The Fuse 1 brings with it new technology, namely Surface Armor, what Formlabs describes as a semi-sintered shell that protects the surface of the part as it prints.

This patent-pending technology aims to enable ‘great surface finish, high reliability, and high refresh rates’. We don’t know much more than that, but we have a chat with Formlabs’ David Lakatos scheduled for later this week to find out!

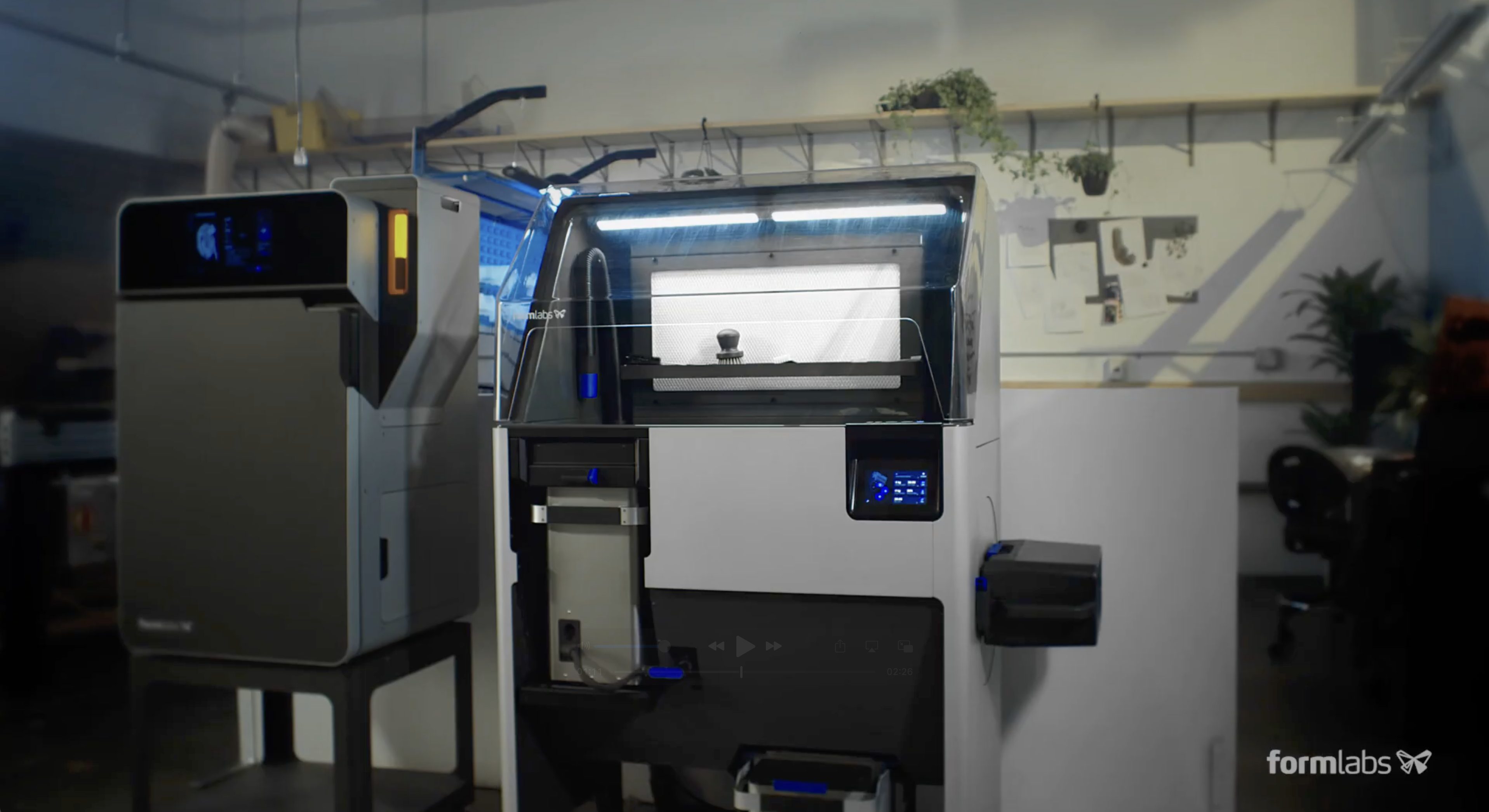

The Fuse Sift depowdering machine also looks interesting, combining a break out station, material recovery and powder recycling station (including an integrated mixing capability) all in one.

How much does a Formlabs Form 1 cost?

The Fuse 1 is available for order now starting from £13,999, with the complete setup starting from £23,925

You’ll also need an explosion proof, ATEX certified, vacuum device and a bunch of other ancillary equipment (Henry isn’t going to cut it).