It’s rare nowadays for a product development team not to have access to at least a desktop 3D printer, with much of the additive action now on the desks of designers and freed from the gatekeeper of a dedicated facility or bureau.

Cost effective, hardy, offering a good choice of materials, primarily for prototyping but capable of producing presentable models with the minimum of fuss and set-up, this diverse list of 12 technologies and price points represents some of the best 3D printing options out there.

As ever cost is a huge consideration, and it’s worth noting that hardware vendors bracket the ‘Professional’ market as being anything from £2k to £100k.

Remember to factor in any service plans and peripheral post processing equipment, and keep in mind material costs. Many of these 3D printers are now capable of building incredible parts using composite filaments or specialist resins. However, if you’re producing lots of simple volume models and the occasional fixture, FDM materials like PLA or fast draft resins are far more economical.

Markforged Mark Two

While several FDM 3D printers on this list are capable of 3D printing composite filaments, it was Markforged that pushed the ability with the continuous fibre reinforcement technology featured in the Mark Two. Capable of serious end-use parts, this is handled by Markforged’s Eiger software, which supports the design decision-making, but requires learning to reach its full potential. The Mark Two remains top of many engineers’ wishlists, thanks to its bulletproof build, workhorse output and ability to produce parts capable of replacing machined metals.

» Technology: FDM

» Max Build Area: 320 x 132 x 154mm

» Price: £££

markforged.com

Zortrax M200 Plus

Zortrax’s entry-level M200 Plus is billed as a robust, simple-to-operate workhorse. Its Polish creators have simply dubbed it a “basically reliable printer”, and they’re not wrong. That said, each unit still boasts a built-in camera, touchscreen controls, WiFi connectivity and the ability to be quickly set up as part of a print farm. Meanwhile, peripherals – such as an air filter and part vapour smoother – can be added to the set-up if needed, while costs can be kept down by selecting from among a huge array of third-party filaments.

» Technology: FDM

» Max Build Area: 200 x 200 x 180mm

» Price: £

zortrax.com

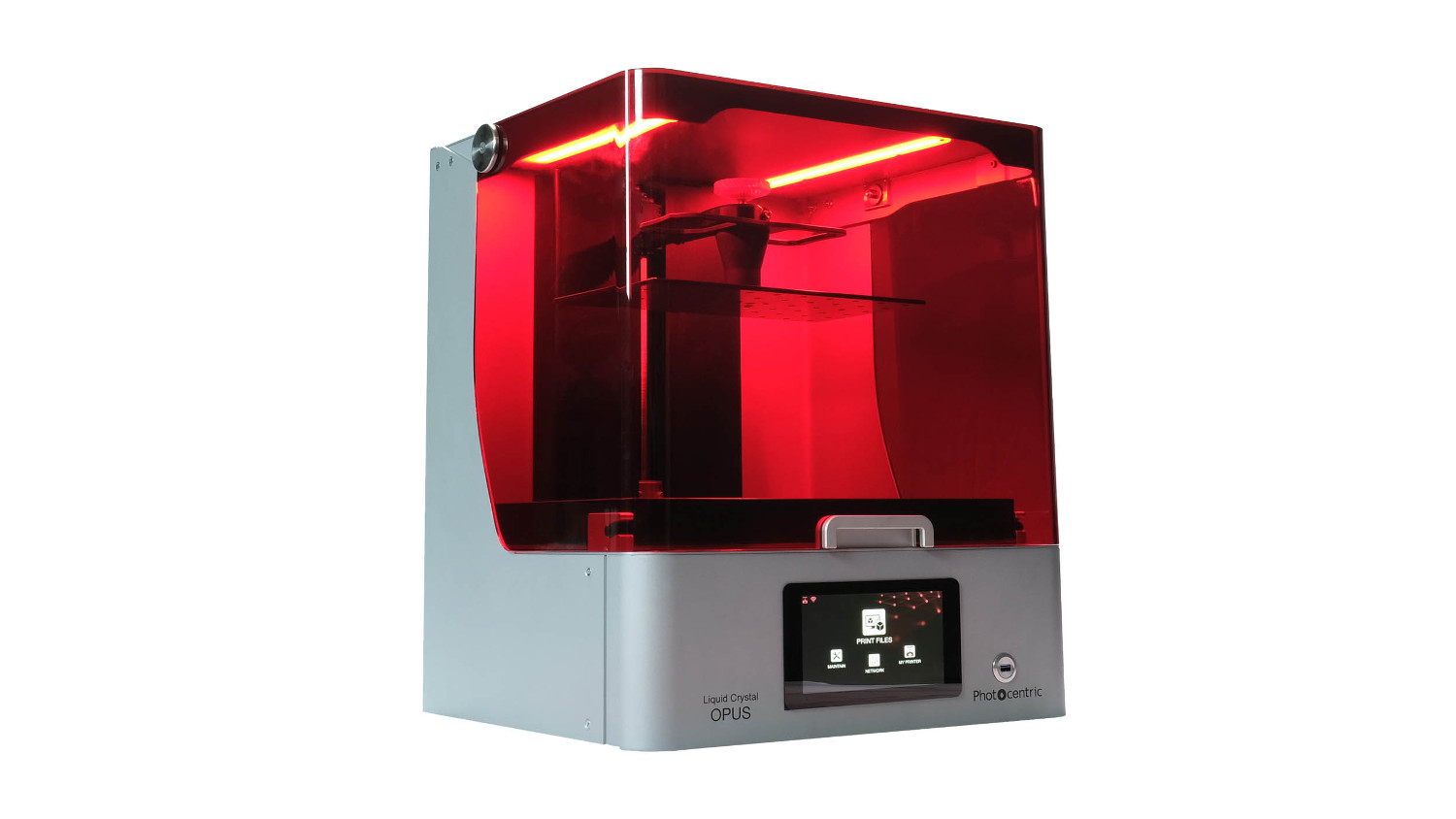

Photocentric Liquid Crystal Opus

The newest 3D printer on this list, the Opus eschews lasers and light projectors, opting instead for a 14- inch 4k LCD screen to cure the resin.Photocentric’s UK-based engineers have worked to optimise its light distribution for repeatable, uniform cures that, when coupled with the 3D printer’s aluminium construction, Trinamic motor drivers and new resin vat design, should allow it to produce high-accuracy parts time and time again. A selfcleaning mode, interchangeable build platforms, and a purpose-built, 7-inch display add to its ease of use.

» Technology: SLA

» Max Build Area: 310 x 174 x 220mm

» Price: ££

photocentricgroup.com

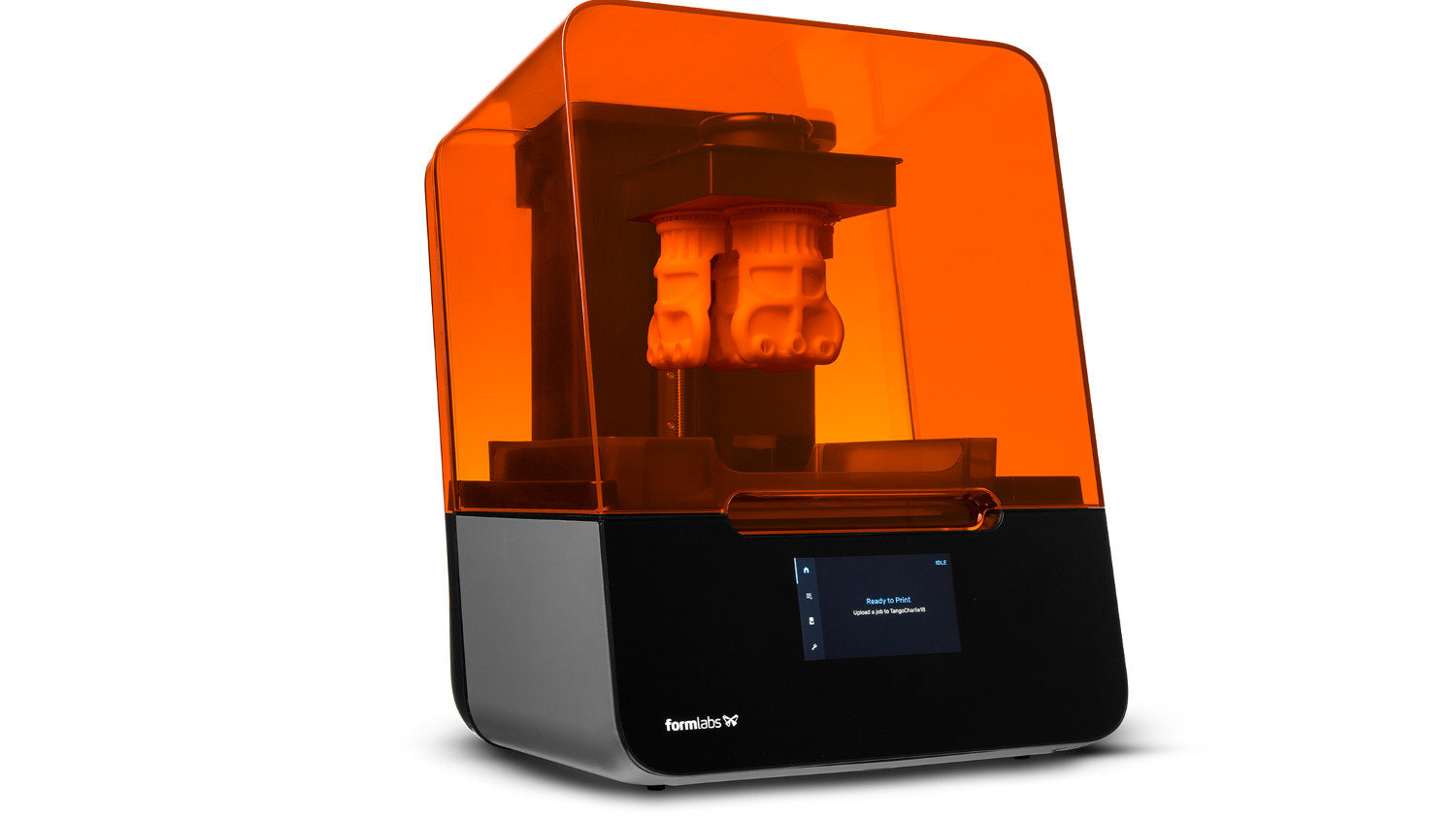

Formlabs Form 3

The Form 3 is Formlabs’ most revered 3D printer to date, and it’s not difficult to see why. The Form 3’s custom light unit allows for pinpoint detail and reduced layer visibility, but also aids things like translucent part clarity. The Low Force Stereolithography technology used in this model means that you should be able to get away with fewer supports, meaning faster prints and less waste material. The resins developed by Formlabs can tackle pretty much every task, from fast print early concepts to tough testing, and even ceramics.

» Technology: SLA

» Max Build Area: 145 × 145 × 185mm

» Price: ££

formlabs.com

3D Systems Figure 4 Standalone

The surface quality of parts from 3D Systems’ entry-level DLP 3D printer is something to behold, especially considering the machine’s speed. Developed originally as part of an automated factory configuration of 16 print engines, the standalone version is a rapid, office-friendly 3D printer capable of producing high-detail threads and internal structures. Its mass-manufacturing origins means it inherits good repeatability and can handle a wide range of resins, recently adding new Tough and Flame Retardant materials to the list.

» Technology: SLA

» Max Build Area: 124.8 x 70.2 x 196mm

» Price: ££££

3dsystems.com

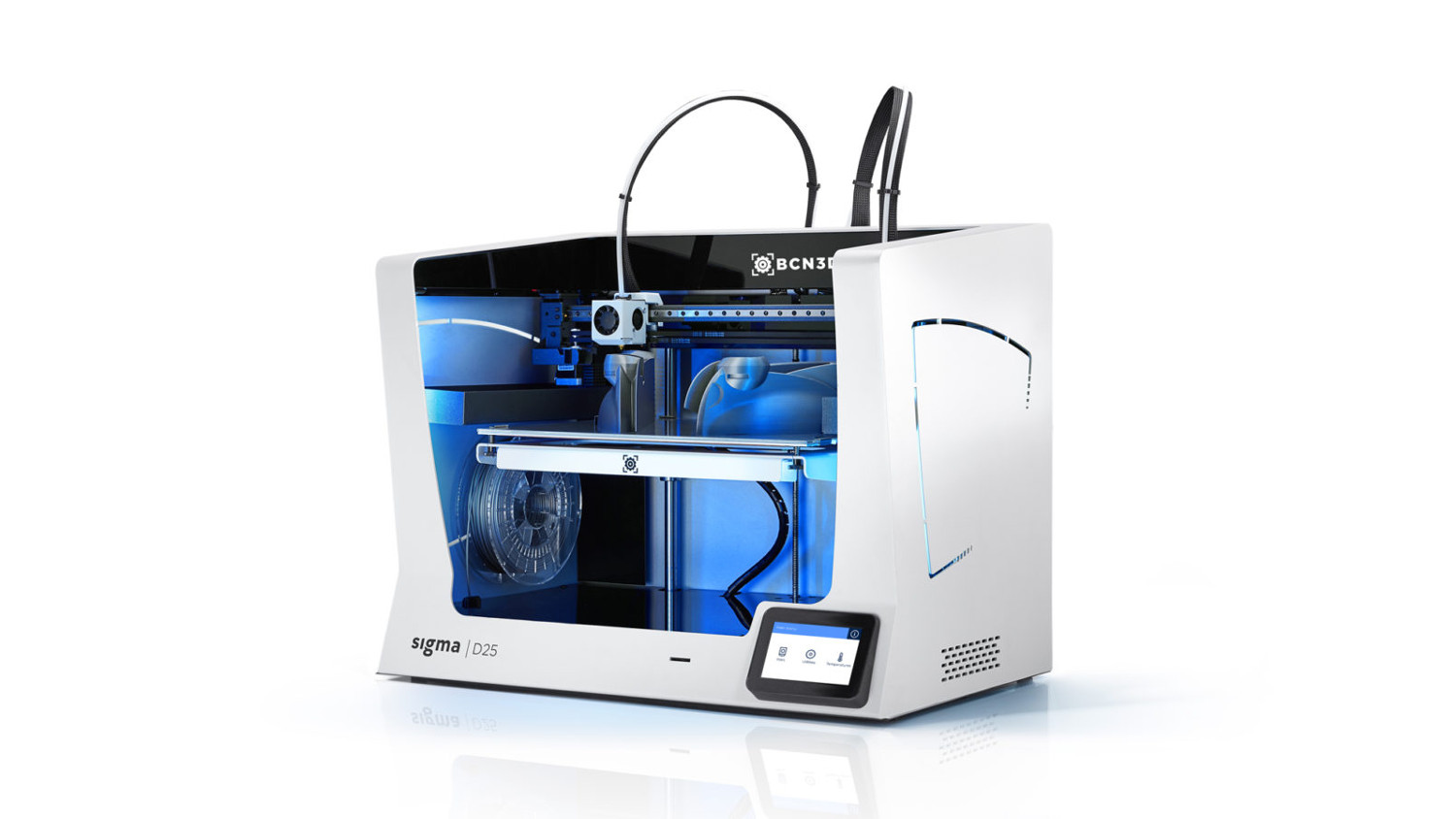

BCN3D Sigmad25

Those looking to build bigger parts on their desktop might want to step in the direction of BCN3D and its entry-level model. For this price, you get a lot of ability. As well as the generous print area, you also get IDEX (independent dual extrusion), allowing you to drive the two filament extruders simultaneously. That means two materials can be used (allowing for a support material), or you can effectively split the print area in two, with an extruder working each side, to produce duplicate models in a single build.

» Technology: FDM

» Max Build Area: 420 x 300 x 200mm

» Price: ££

Bcn3d.com

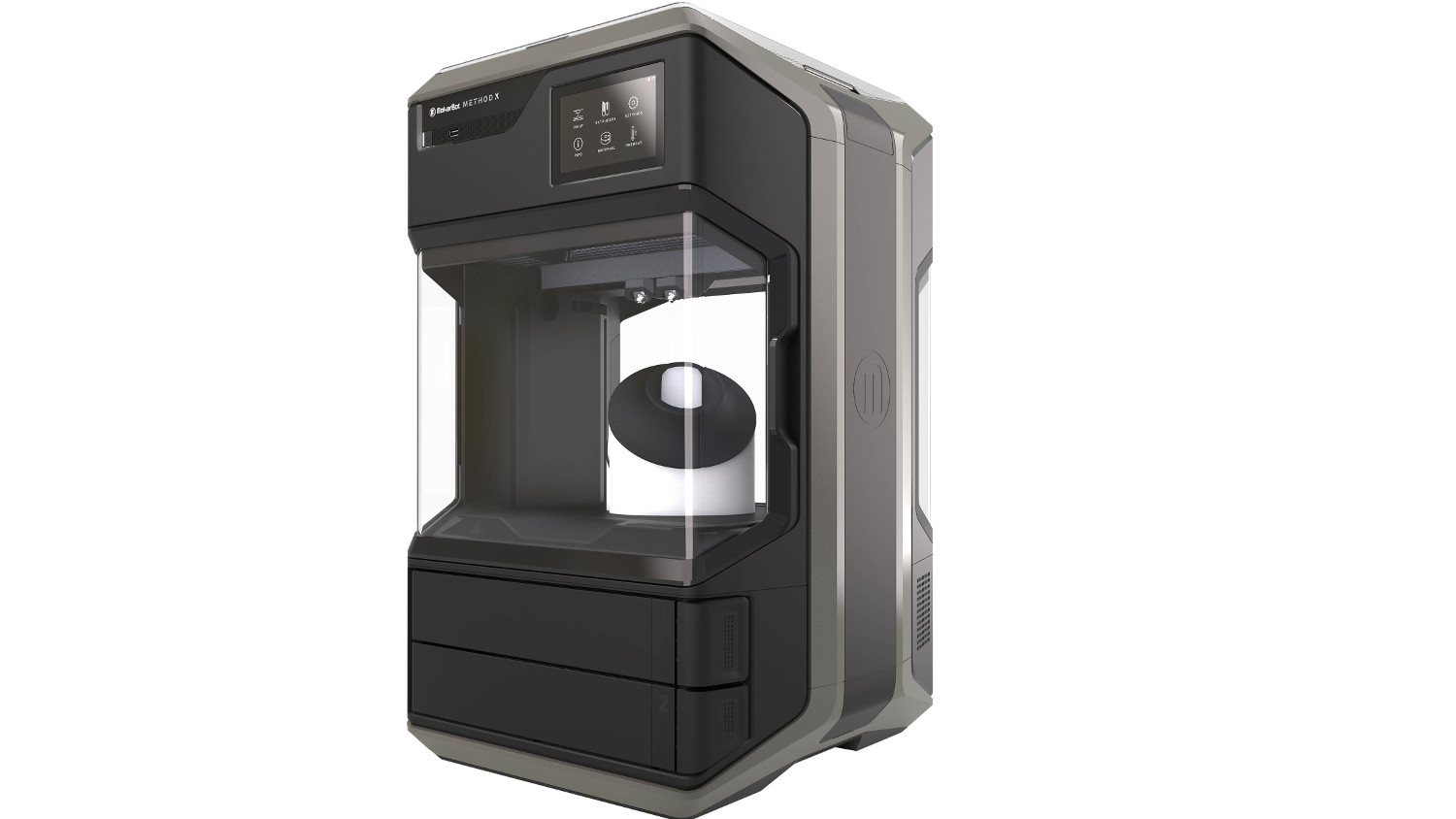

MakerBot Method X

The Method X is the most advanced option from MakerBot and its catalogue of 3D printers purposebuilt for professional use. It can print in the full range of MakerBot polymers and composites, including ABS and a soluble support material. With excellent accuracy and part strength, thanks to a 110°C-heated build chamber, as well as 21 different sensors onboard and some nice design touches, the expertise lifted from parent company Stratasys’ industrial FDM machines is packaged up at a tempting price point.

» Technology: FDM

» Max Build Area: 190 x 190 x 196 mm

» Price: ££

makerbot.com

Roboze One Xtreme

Despite being the bambino of Roboze’s family of advanced polymer 3D printers, the Italian manufacturer has hardly held back on its ability. While this machine lacks the superhigh- temperature build chamber of the brand’s more expensive options, there’s plenty here for users to love – from its nippy printing speeds to an array of sensors that put it firmly in the ‘professional’ category. Carbon PA, Flex-TPU, PP, Nylon and Strong- ABS are some of the materials that will push prototyping into the realms of proper end-use parts.

» Technology: FDM

» Max Build Area: 300 × 200 × 200mm

» Price: ££££

roboze.com

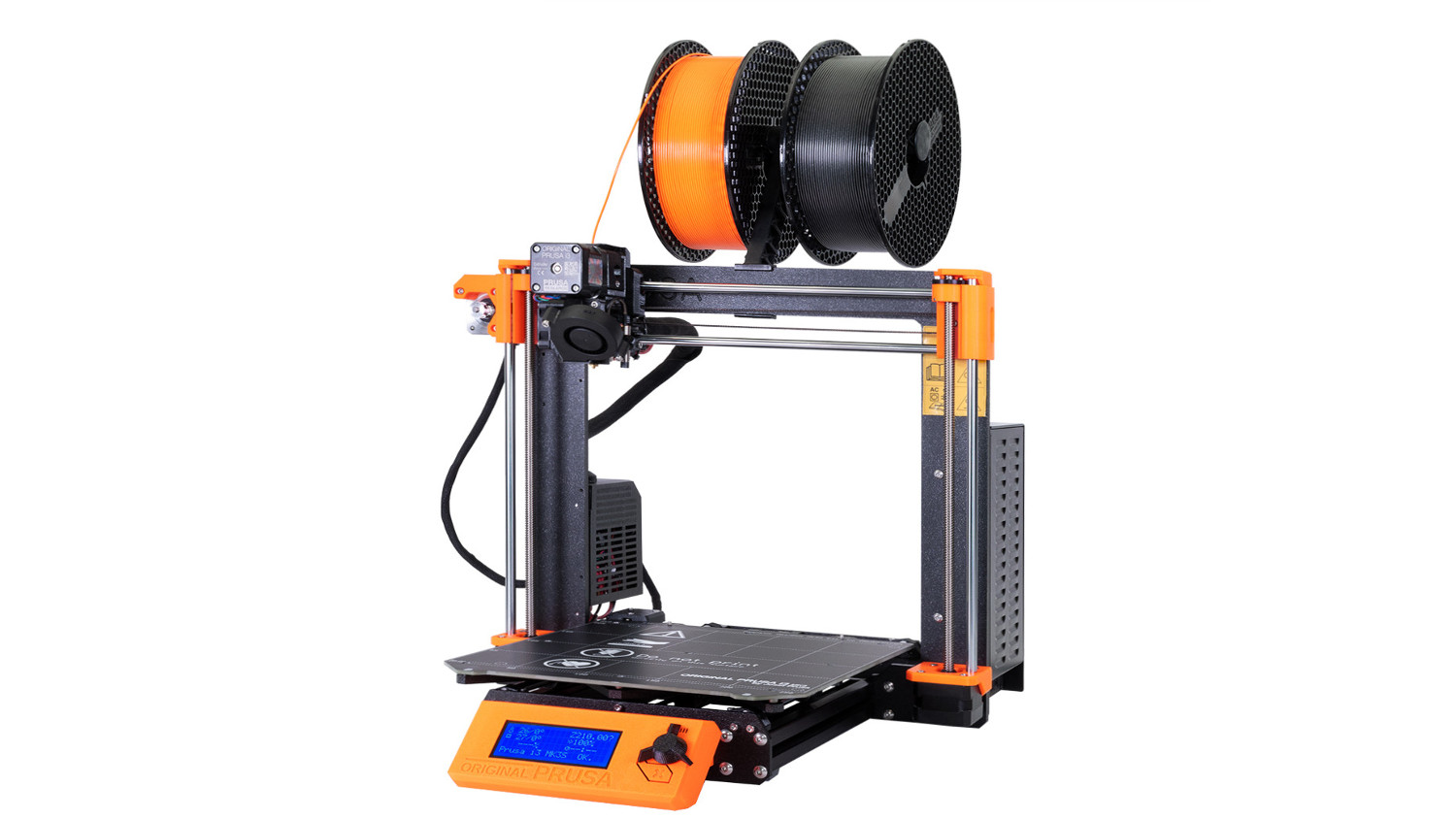

Prusa i3 MK3S+

Beloved by makers, the Prusa brand is synonymous with getting surprisingly good results from what is easily one of the most affordable models on the market. Its prosumer background (it’s also available as a DIY kit starting at £577.69 exc VAT) and loyal following mean you’ll never be short of someone to ask for guidance.

However, you’ll likely need to spend more hands-on time getting to know your i3 in order to get the best from it. But, for the cost and results achievable, plus the ability to replace/ upgrade parts, it’s an excellent option.

» Technology: FDM

» Max Build Area: 250 x 210 x 210mm

» Price: £

prusa3d.com

Stratasys J55 Prime

The J55 Prime’s abilities are a step closer to the top end of Stratasys’ J-Series, making it one of the most versatile (and expensive) options here. With Pantone-graded full-colour printing available, users can print directly from Keyshot renders via the 3MF file export. On top of that, the Prime also adds a version of Stratasys’ digital materials portfolio, allowing users to print a range of shore values by mixing resins. Users can add snap-fit closures, or over-moulded rubber grips, along with colours and graphics, all within the same print.

» Technology: Polyjet

» Max Build Area: Circular tray offers 1,174 cm2

» Price: £££££

stratasys.com

Ultimaker S5 Pro Bundle

The S5 bundle that adds on a materials handling bay and air filter is a greatvalue option for a solid FDM 3D printer. Designed for serial production of parts, the materials fed through the base means the printer can be left unattended while you continue with design work. A touchscreen display helps with easy operation, while those wanting to tinker with settings can do so easily within the Cura software. As well as removing ultrafine particles, the filtration hood also better controls the environment inside the printer, resulting in more reliable prints.

» Technology: FDM

» Max Build Area: 330 x 240 x 300mm

» Price: ££

ultimaker.com

Formlabs Fuse

Bringing SLS technology into an office is a bit of a stretch – the necessary cleanup and powder processing equipment means that this is definitely a workshop device. But the size, price and useability mean that sintering nylon is no longer simply for those with OEM budgets or outsourcing. With Nylon 11 and 12, its materials offer high-strength functional parts while the modular build platform and ability to stack parts keeps throughput high. While the extra upfront costs for the peripheral Fuse Sift powder recovery system jerk the initial price upwards, material reuse rates are reportedly higher than industry averages.

» Technology: SLS

» Max Build Area: 165 x 165 x 300mm

» Price: ££££

formlabs.com