Rapid Prototyping. It’s a phrase that’s been glossed over in recent years. As the MakerBots, the RepRaps and the 3d printing bandwagon have garnered the column inches, TV minutes and tweet counts over the last two years, many have forgotten the background to much of this technology.

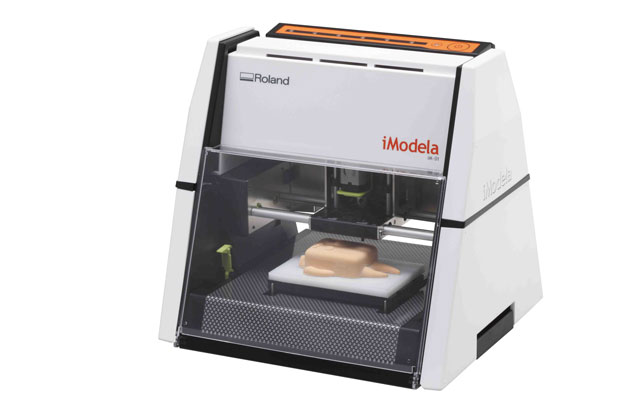

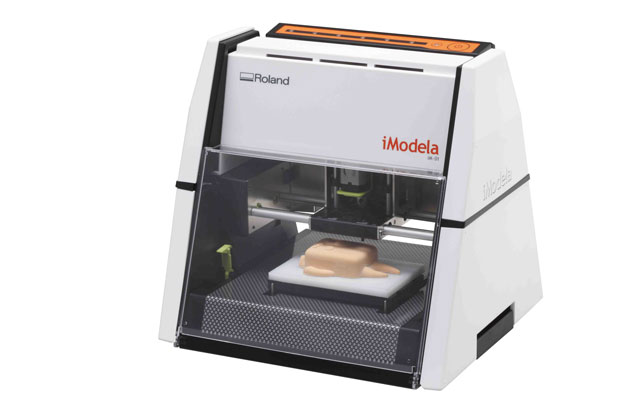

The Roland iModela is compact but fully functional

Now, while the mainstream media cooks up all manner of nonsense about the rebirth of manufacturing through the adoption of an ABS sausage extruding machine, those at the business of the design to manufacturing process, will recognise that these machines are prototyping machines — to a greater or larger extent.

What’s interesting is that while the world has gone nuts for 3D printers, the other technologies often used in the prototyping process have been going through a quiet revolution at the same time. Smaller, cheaper machines, available to a much wider audience.

In the world of CNC machines for the design office or design workshop, Roland has gained a reputation as a leader. If you’re not familiar with the name, Roland is one of those curiously Japanese organisations that seemingly has its fingers in many different and often diverse, pies.

Musicians amongst the readership will recognise the name Roland as being a provider of electronics; keyboards, synthesisers, electronic drum kits, recording kit. They’ve even got a digital accordion. The guitar fiends amongst you will also know the company’s sub brand, Boss, masters of the effects pedal.

Roland also has interests elsewhere, it has a range of printers for the reprographics market, plotters and such for the design office and much more.

But for the designers and engineers out there, Roland is also known for the activities of its Design Group. It’s in this group that you’ll find not only its MDX CNC milling machines as well as a number of 3D scanners. These have been on the market for over a decade, have sold in their tens of thousands across the globe and are a core part of many workshops.

While the product range for CNC milling has been established for some time, with a reasonable entry level, it was with some surprise a year or so ago that the company launched the iModela. It looks different to Roland’s other CNC machines; it’s very small, it’s compact and it’s 500 quid. And it’s this that we’ll be taking a look at this month.

Out of the box build-up

Anyone that’s got involved in the set-up of machining equipment will be more than familiar with the process of set-up and calibration.

The iModela differs from the usual course of events. It arrives in a hard case and opening it up, you’re presented with a set of components that, with just a cursory glance at the manual, gets you up and running in no time at all.

For those experienced with CNC machines, you’ll be surprised that this device is essentially a small drill bit collet chuck, driven by one of those motors from a radio controlled car.

The cutter is driven in the X axis by a linear guide screw, the platform beneath takes care of the Y and Z axis travel. Once everything is in place, you close it all up (which is delightfully origami-esque), snap the locks into place and plug it into the power and eventually, your laptop via USB.

It’s a small unit, about the size of Weetabix box and has the look of an extra from Pixar’s Wall-E, rather than a CNC machine.

Software set-up

The software set-up requires that you install the base level systems — the controller software (think: just like your more industrial scale brothers, even with the big red button) as well as number of applications to assist with design. Here, you have a number of options.

The iModela Creator system gives you a vector based design system, ideal for creating name plates, smaller engraving jobs and such. But for those of us in design, we really want to be able to machine 3D forms. For this you’ll need to download and install Roland’s ModelaPlayer system.

This gives you the ability to import 3D files (typically done via STL) and set-up a machining job.

Toolpath set-up

You begin by importing and orienting the part, setting up the datum, the billet as well as offsets from the part form, so that it can be machined in the block.

Despite the simple nature of the system, you can do some quite advanced things, multi-sided machining and such. It just takes a little forethought about how best to produce the form you want.

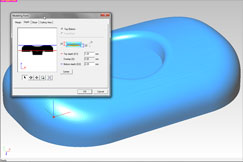

You then create the toolpaths, using presets for the material you’re machining (the iModela will cut most plastics, woods, modelling foam and such — but can’t handle conductive materials so no metals).

If you want to dive in, you can change all the parameters, speeds, feeds, cutter dimensions, cutting strategy — the whole shebang. It works exactly the same as a standard mill.

It can even give you a visual simulation of material removal, so you can see what you’re going to get.

Once complete, the toolpaths are output and ready to read into the controller application.

Model cutting processing

Model prep is pretty straightforward.

Take your material block, stick it to the machine bed (using double sided tape), move the cutter to the datum point and set the machine going.

One thing that you’ll notice is that this is a noisy little bugger. It’s not as bad as a 5 -axis high speed machining rig, but when it’s running at full tilt, it’s pretty noisy.

If you’re machining a small name badge or other detail, it’s not too bad, but if you’re cutting out a more substantial model, then it needs to be borne in mind when installing the machine.

Results and conclusion

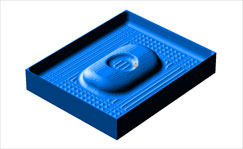

As with all such machines, it’s the results that count and how they fit into your workflow. The fact is that the iModela is a small machine. It can handle parts up to 86 x 26mm and up to 55mm in the z height. It’s clear that you’re not going to produce massive parts on this thing.

That said, what it can do is machine out small, intricate parts and give you small details where needed. If you’re building presentation models in house, then there are some parts that just can be done effectively on a 3D printer of whatever flavour.

With the iModela, you can machine these in a pretty usable time frame. It won’t be the centre piece of a prototyping workflow, but I can completely see it fitting in as an ancillary machine to assist where needed.

If you’re in the jewellery industry, then its also worth noting that Delcam have retrofitted this machine with a rotary axis for machining investment casting waxes along with some of their own software magic (see delcam.com for more details).

All in all, the iModela is a decent bit of kit. Limited, yes, but if you’re looking for something larger, then it’s worth looking at the other products in the range.

Fancy moving up?

The iModela is a wee little beast and while I’m sure most will scoff at its small stature, it could find a place in quite a few design offices. That said, we all want bigger and better prototypes, the ability to build at full scale. This is where Roland’s extensive product range comes into its own. From smaller CNC mills that combine cutting with 3D scanning, up to fully automated 4th axis and auto tool-changing, it’s all there. Let’s look at two of the best:

MDX-40A

While not the smallest of the MDX range (that’ll be the MDX-20 that also doubles as a probed based Rev eng device), the MDX-40 is where things start to get serious.

With 305 x 305 x 105mm as a machining area, optional rotary axis mechanism and 3D scanner add-on, it’s bigger than most 3D printers, and gives you a nice spread of possible materials to cut with — it is also worth noting that the MDX-40A won’t do metals.

Price: £5,499

MDX-540

The is a big boy. It can be fitted out with automatic tool changers and rotary axes. It’ll cut almost anything you need it to (they limit it to “light metal”).

And from speaking to companies that already have them, it’s pretty much bullet proof. At just shy of 14K, this brings it in league with other CNC machines out there, but for the design office/workshop, this is about perfect and about as big as you can get for parts up to 500 x 400 x 155mm

Price: £13,999

| Product | iModela |

|---|---|

| Company name | Roland |

| Price | £499 |