It might not be the most eloquent of descriptions, but Nvidia’s Graphics Technology Conference (GTC) has always been a bit of a geek-fest. Scientists, researchers, programmers and developers get together every year to talk about GPU computing, high-end graphics and Nvidia’s parallel computing architecture, CUDA.

Ludwig Fuchs, CEO of RTT, introduces a new ‘point-of-sale’ project for car dealerships

While GTC 2013 was no different, it did mark a noticeable expansion into design and engineering. There were new product announcements specifically targeted at CAD and a dedicated conference stream featuring household names such as Boeing, Nike, PSA Peugeot Citroen and Chrysler.

Perhaps the biggest marker of the shift going on at GTC was Nvidia CEO, Jen-Hsun Huang’s 150 minute keynote. A good chunk was dedicated to CAD, the pinnacle being the launch of the GRID Visual Computing Device (VCA). There was even a guest appearance by SolidWorks VP of R&D, Gian Paulo Bassi.

Over the years Nvidia has made a habit of showcasing the capabilities of its new generation GPU technology through example and at GTC this year Jen-Hsun Huang pulled a couple of show stoppers out of the bag.

In the past the demos have been good, but nothing to write home about. This year you could literally see jaws drop in the audience.

Huang introduced WaveWorks, an incredible Beaufort-scale ocean simulator, where physics processing meets computer graphics, powered in real time by a GeForce GTX Titan GPU (2,600 CUDA cores. 4.5 teraflops).

From a slightly choppy 6.0, up to Hurricane-level 12.0 the simulation showed a boat responding to the waves on the open sea. Thousands of water pressure sensors are used to simulate the movement: spray gets picked up by the wind, rides the deck and then falls back to the ocean, all in incredible detail.

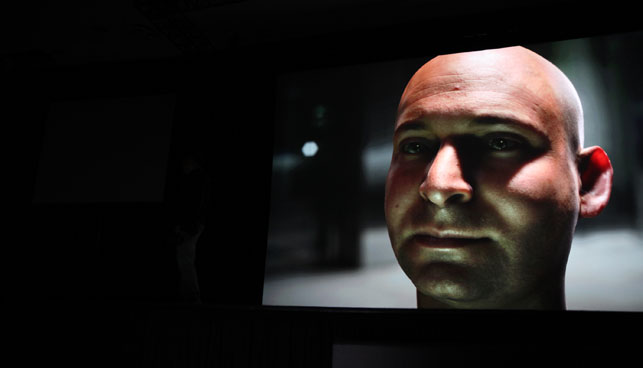

Topping this was FaceWorks, a stunning facial expression simulator, which was as real as anything one sees in films but, again, calculated in real time.

We realise these are demos, specifically developed to show off the computational performance of the new generation GPUs, but both have to be seen to be believed (check it out – 8 mins in) and FaceWorks – 9 mins in.

FaceWorks, a stunning facial expression simulator

Both show a glimpse of where real time animation and simulation could go in the future. It was a real talking point among delegates as we headed into the coffee break.

Remote graphics

One of the major recurring themes of Huang’s keynote was remote graphics. The Nvidia CEO explained the reasons behind this growing technology where the processing is done in the cloud or on a server and the graphics results are streamed to a mobile device or thin client.

Huang highlighted that workers no longer sit at desks, often bringing their own mobile devices to work, adding that it will be almost ridiculous to be given a company computer in the future.

Data is also getting larger and larger, he said, stressing that copying files to and from servers to work with data locally was the antithesis of staying in sync.

CAD data has become so large that it makes no sense to copy it to your PC, he said, adding that Nvidia has customers that literally spend 24 hours copying huge datasets around, only to find that by the time they’ve made their edits and copied it back the original data has changed.

Huang highlighted the groundbreaking work that Applied Materials, a provider of manufacturing solutions for the semiconductor industry, had done developing an internal desktop CAD cloud.

The company put GPUs in servers and developed a remote graphics system capable of serving a global engineering workforce, round the clock, supporting a collaborative design process. See page 38 for more on this exciting project.

Moving on Huang acknowledged that not all businesses have such levels of technical expertise.

“What if you’re a small to medium business and you want to work in a modern way, without the support of a large IT department, and you do your work on a workstation but you want to be able to collaborate,” he asked. “You just want to walk away from your desk and bring all of your stuff with you so you can do a design review.

This teed him up nicely to introduce one of GTC’s major announcements, Nvidia’s ‘first ever system’ the GRID Visual Computing Appliance (VCA).

GRID VCA is designed specifically for SMEs who want the flexibility of a remote graphics solution but don’t have the in-house knowledge to deploy one.

The 4U server features up to four Xeon processors, 16 GRID GPUs plus all the system software, including the hypervisor that creates and runs up to 16 virtual machines.

Huang explained how the VCA can be connected to multiple devices, which simply need to download and install a GRID client.

“When you pop open this client your virtual workspace, your remote workspace, completely GPU accelerated, shows up,” he said. “It doesn’t matter if it’s a Mac, it doesn’t matter if it’s a PC or even an Android thin client, the computer in the back runs the applications and all they see is the pixels. And it’s doing it so fast you think the pixels are being generated by your computer.”

SolidWorks and Nvidia GRID VCA

SolidWorks is often used by hardware vendors when they want an example of a 3D CAD application so it’s not uncommon to see it in demos. However, it was to some surprise that Huang was next joined on stage by SolidWorks VP of R&D, Gian Paulo Bassi.

SolidWorks is very much a proponent of ‘CAD in the cloud’, including private clouds, and the Nvidia GRID VCA seems to fit in well with this philosophy, particularly as the majority of its customers fall into the small to medium sized company demographic.

To solidify this partnership SolidWorks will be one of the first software vendors to certify its software for the appliance.

Bassi, who spoke about the future of SolidWorks at DEVELOP3D LIVE in April, talked about his customers’ growing need to access their data anytime, anywhere from any device, and with engineering grade precision.

Huang then highlighted some of the early feedback Nvidia had received from SolidWorks and its partners citing flexibility as a recurring theme. He explained that Nvidia GRID VCA can support workforces that change in size and be assigned to different groups as workflows change during the product development process.

Deployment was also identified as a key benefit, as the software only needs to be installed on the Nvidia GRID VCA once and can still reach many users.

Nvidia CEO, Jen-Hsun Huang was joined on stage by SolidWorks VP of R&D, Gian Paulo Bassi to present SolidWorks running on a private cloud

“[Design firms] can instantly create a network of companies in order to collaborate on the design of a new product and they can very quickly and safely show the result of their ideas to customers,” added Bassi. “They can take a simple device anywhere in the world and the data is safely in their vault, in their office.”

RTT, Audi and VCA

The idea of putting advanced, interactive 3D models into the hands of customers was expanded on by Ludwig Fuchs, CEO of RTT, who joined Huang on stage to introduce a new ‘point-of-sale’ project for car dealerships.

In 2012 RTT developed a realtime configurator for a digital showroom at Audi City in London. The system uses multi-touch tablets and huge powerwalls so customers can create personalised ‘life-size’ car designs, based on individual preferences for colourways, interiors, materials and components.

Fuchs explained the vast resources, hardware and on-site expertise required to deliver these digital showrooms. The challenge moving forward, he said, is to make the technology available to more dealers and consumers.

Nvidia GRID VCA will help enable this on a smaller scale, streaming to two devices: a tablet used by customers to customise the car in real time, and a Smart TV, which will display the results.

The benefit, of course, is ease of deployment: there is no need to install a powerful workstation on site, nor maintain the software. All that’s required is a fast Internet connection and off the shelf consumer hardware.

Design and engineering

This year GTC introduced a dedicated design and engineering conference stream. These weren’t highly technical sessions; instead customers shared their experiences with GPU-based workflows ranging from design and simulation to visualisation and virtualisation.

Galen Faidley gave an insight into immersive visualisation at Caterpillar and how VR has become an integral part of its global product development process.

Caterpillar develops a massive range of machines, manufacturing over 350 products, most of which have a different function.

As a result simulation and visualisation plays a huge role in helping evaluate designs prior to building costly physical prototypes.

Assessing human-machine interaction is a huge part of this, but instead of relying on virtual humans, Caterpillar uses VR to enable actual people – designers, engineers, customers – to interact with a virtual machine.

Faidley gave some great examples of how VR has helped Caterpillar at the early stages of the design process, not only to improve its products, but to save vast amounts of money.

For the design of a new bulldozer, Faidley explained how the design team looked into operator visibility. One of its designers had the radical idea of placing a single column for the cabin’s roll cage directly in front of the operator.

Caterpillar was able to prove this concept using VR. It made a Styrofoam mock-up of a cabin, that an actual operator could sit in, then invited customers to experience the virtual design. Customers could instantly see that visibility would be improved and the new design was approved.

Faidley admitted that had they not been able to test it out inexpensively with immersive visualisation the new design would never have been built.

On another bulldozer project VR helped Caterpillar save $500,000 in tooling costs, identifying an assembly issue moments before committing to steel.

Nike’s Russell McMurdie lifted the lid on the highly dynamic rendering workflow that Nike uses as part of its design / review process.

The presentation included a feast of photorealistic renderings, including the legendary Nike Air Force One shoe, that play an essential role in getting a product signed off for manufacture.

Nike’s design process starts with a sketch, which then evolves into a model using a number of 3D tools, including one that is specifically designed for modelling shoe uppers.

To create the visualisations the model is then taken into Maya via the OBJ format and automatically cleaned up using some custom scripts. Finally it is brought into Bunkspeed, where Nike’s custom materials are dropped on to create the stunning photorealistic renderings.

According to McMurdie, custom materials for Bunkspeed are essential so visuals will accurately represent how the finished design will look. “Our material designers get a sample of the materials,” he said. “Depending on the material we’ll either go and photograph it or scan it and then take it into Photoshop. Then we have programs that export out all of the different maps we need and they’re all super, super light and fast and quick.”

For each unique design, stills and turntable animations can be rendered in seconds thanks to an in-house GPU render farm that boasts a whopping 24 Nvidia Tesla C0275 GPUs. This proves invaluable when last minute visuals are needed for meetings in order to get new designs and colourways signed off.

In addition to the speed benefits, McMurdie explained that using the GPU render farm frees up his local machine so he can continue to work at full speed.

Boeing talked massive model visualisation and shared details of how its complex 3D data is made available on the shop floor to help its mechanics build airplanes and assess quality.

Running a web-based application on standard 32-bit laptops users can interactively rotate, dynamically zoom and interrogate geometry and dimensions. To help maintain frame rates, the system dynamically adjusts the level of detail according to where one is in the model. Parts can be viewed in context or isolated for detail.

When one considers that the Boeing 787 is a 10GB model with 650 million polygons and 237,000 parts this is hugely impressive, but one couldn’t help wondering if the process would benefit from a remote graphics implementation running tablets off a system like the Nvidia GRID VCA.

Remote graphics did get lots of stage time at GTC, most notably from Applied Materials who did an inspirational presentation on CAD in the cloud. Brendan Hickey’s work stood out, not only for the scale of the global project, but because it all started four years ago, at a time when remote graphics over LAN, let alone WAN was still in its infancy.

Applied Materials is a global company that designs and manufactures the massive machines used to manufacture semi-conductors, flat panels and solar photovoltaics. With the time to market on these products critical, the lead-time on the machines that manufacture them is ridiculously short — a matter of weeks to design, release, manufacture and ship to customers, Hickey explained.

To handle this high-pressure workload the company has a huge concurrent engineering team spread across 90 locations in 19 countries.

As you can imagine the big challenge is data. Hickey explained how engineers at each site used to check in and out data from local servers to powerful 3D computers. Each local server then had to sync up with five other sites, but because of the huge amounts of data involved this often left engineers waiting for syncing to finish and also led to sync errors.

Applied Materials took the bold move to develop a remote graphics solution using blade workstations. It reduced the number of data centres to three, and between Austin, Amsterdam and Bangalore served a total of 3,000 engineers throughout the world including countries as far away as Japan.

Engineers traded high-performance gaming PCs for laptops, a move that was initially greeted with some scepticism, but they soon came around to the idea, said Hickey.

“They kind of realised oh, hang on a minute, I can just lift my notebook up off my desk and go wherever I want to go within the building,” he said. “Or I can go from home, I can work from supplier sites, I can work from the hotel. So they could work on these massive assemblies that we manage no matter where they were so long as they had a good Internet connection, they had full access to their desktop in their private cloud.”

Hickey shared some conservative estimates of the savings achieved through its ‘CAD in the cloud’ system: multi site synchronisation transactions reduced fourfold, errors by three and a half, load times by two. The number of engineers working from home on evenings and weekends also rose.

It’s one thing to learn about the technology behind remote graphics, but another entirely to hear about its successful implementation on a large scale project.

From speaking with Hickey the one bit of advice that really resonated with me was ‘you can always buy bandwidth, but you can’t do anything about latency.’ In fact, this is exactly why Applied Materials had to build a third data centre in Amsterdam.

They had hoped to cover its entire global team from two sites, but poor latency in Israel meant they had to bring the data source closer.

Conclusion

Nvidia’s GTC will no doubt mean different things to different people, but for designers and engineers it’s certainly an excellent opportunity to learn how peers are implementing the very latest in GPU technology.

For me, the event opened my eyes to virtualisation and remote graphics and the important role it is set to play for CAD users in the coming years. I’ve always considered it to be an interesting technology for large enterprises, but the introduction of the Nvidia GRID VCA has made me understand how it can also benefit small to medium sized firms.

I’m not yet convinced that remote graphics is applicable to everyone — I’m certainly not ready to trade in my desktop workstation — but the flexibility it offers internally or remotely across multiple sites, is making it harder to ignore.

If you’d like to learn more about remote graphics and virtualisation, I’d recommend you check out the GTC website where many of the presentations have been made available.

www.gputechconf.com

To find out more about Nvidia GRID VCA read our in-depth analysis

Some interesting news for SolidWorks users at Nvidia’s annual graphics technology conference

Default