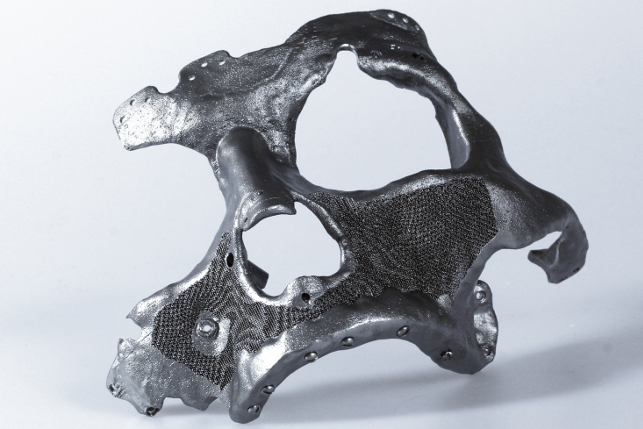

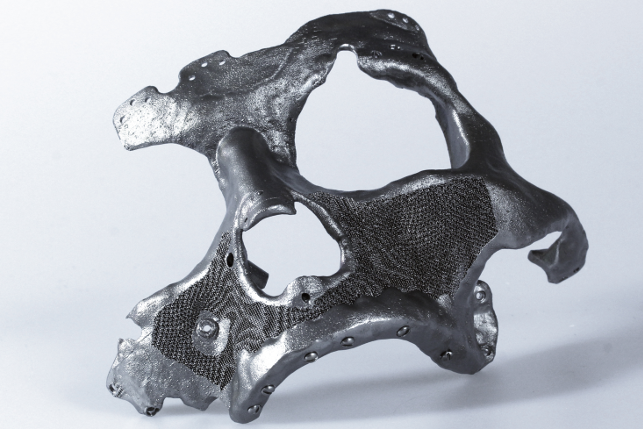

An implant used in facial reconstruction surgery and built using Within Technologies’ software

In May 2014, Autodesk acquired Within Technologies, a UK-based developer of design and simulation software for advanced manufacturing.

One of the company’s main areas of focus has been creating software to support the use of additive manufacturing in the biomedical space, with its products used in the creation of cranial flaps and jaw implants, for example.

This is an area set to boom. According to recent estimates from Transparency Market Research, the market for 3D printing in medical applications is set to rise from $354 million in 2012 to $965.5 million by 2019.

DEVELOP3D caught up with Shane Fox, business development specialist at Autodesk Within, to hear where the most exciting work is going on and where he thinks this market is heading.

DEVELOP3D (D3D): What impact is 3D printing having on medical technology?

SHANE FOX (SF): 3D printing is giving biomedical firms more flexibility when it comes to manufacturing implants.

Traditionally, biomedical engineers created the designs and sent them to be made at manufacturing hubs. But because 3D printing is smaller, cleaner and much easier to use than large, traditional industrial machinery, it allows biomedical firms to bring this process in-house. This can help reduce the turnaround time from the initial design to a finished implant. What could take around eight to 12 weeks, can be cut down in some cases to two to four weeks.

It’s also enabling biomedical firms to create patient-specific implants, or PSIs, which used to be very difficult and expensive. Implants traditionally come in set sizes and are then cut down to size to fit the individual patient.

Today, we can CT-scan areas of the body and use 3D printing to create an implant that replicates the exact shape and size needed. Using customised implants reduces surgery time, because they already fit the dimensions of the patient’s body perfectly and don’t have to be made to fit the patient during the operation.

One example of this that we’ve seen was with a man who lost 85 percent of his face in a car accident. We were able to use a CT scan of his face, upload it to the cloud and use facial recognition software to match the bone structure.

We then designed, 3D-printed and implanted a one-piece titanium facial implant — something that can only be achieved using 3D printing. And because of the structural design of the 3D-printed implant, bones were able to fuse with it, and hair and skin tissues were also able to grow.

D3D: What, for you, are the most exciting developments on the horizon?

SF: 3D printing integrated with nanobiology is the future, to my mind.

There is a new technology emerging where it is possible to take CT scans of bones at a cellular level and see how they grow.

Everyone’s bones grow significantly differently because of how we use them. Being able to extrapolate this level of detail means we’re able to mimic bone structure, convert the data into a 3D-printed file and print an orthopaedic implant.

The benefits of mimicking bone growth are overwhelming: patients have less discomfort; there’s less chance of infection; and a reduced need for a secondary surgery. 3D printing has already increased the success rate of orthopaedic surgeries, but this will dramatically improve it.

D3D: How important is the development of new materials in this process?

SF: Creating new materials is vital for the continued success rate of 3D printing within medicine.

Currently there are four main materials being used – titanium, ceramic and the polymers PEEK and PET – but just as 3D printing techniques develop, so too must the materials being printed.

Over the next couple of years, we’ll see the development of new polymers that will be stronger, cheaper, less toxic and more flexible than current materials being used. We’ll also see the emergence of materials that are able to mimic bone growth which will help with facial and dental reconstructions.

D3D: Do you see any barriers to the adoption of 3D printing in medicine?

SF: One of the biggest barriers is the lack of data available.

The technique is still relatively new and there’s not a lot of data available from previous treatments. What we need are more human use-cases that prove the worth of 3D printing and why it’s better than traditional methods.

The more data we have from surgeries, the more research can be undertaken and this will advance 3D printing within the medical field.

We speak to Within Technologies about how 3D printing could revolutionise healthcare

Default