One of only 12 prototype race ‘Tipos’ ever made, the Alfa Romeo Tipo 33/3 was the Italian manufacturer’s entry into the glamorous world of the late 1960s World Sportscar Championship.

Thanks to KWSP, this Tipo 33/3 is back on the grid

A period of motorsport enshrined in popular culture by the movie Le Mans, the Tipo 33/3 appeared on the big screen alongside the era’s biggest petrolhead Steve McQueen.

Finally finding success in 1971, the works team ran by Autodelta won in Buenos Aires, Sebring and Brands Hatch, before the cars themselves became museum pieces or disappeared. But one of the remaining Tipos is still being run by UK-based Martin Stretton Racing, a leading historic racecar restoration specialist. Like many race teams and restorers, Stretton is faced with a challenge that will only get harder as historic cars get older – the replacement of original parts.

The use of reverse engineering is helping solve the dilemma of replacing crucial components, especially when many of the original parts were custom manufactured nearly 50 years ago.

Racing for a solution

Faced with badly damaged parts that had kept its Tipo 33/3 off the road for several seasons, the team turned to high performance engineering firm KWSP to bring its rare racer back to the grid.

The car’s original, naturally aspirated, three-litre V8 engine was in good working order, with the exception of a problematic front engine cover. Having deteriorated significantly in recent years and been subject to numerous running repairs, the integral working part of the vehicle’s powertrain had become a major issue. The final straw came when the car failed to start.

“This is a rare car – only one of twelve that were made and run by Autodelta – so when we were searching for a replacement cover, the options were limited,” says team owner Martin Stretton.

“We found several alternatives that were close, but none of them were exact matches for our Alfa Tipo 33/3. In the end, we had to explore other avenues.

“Having investigated the pattern making route, using skilled model makers, we realised that this would be a technically difficult project to deliver. It would also be prohibitively expensive.”

It was at this time that Stretton found KWSP, and paid its facility in Brackley, Northamptonshire, a visit.

“Touring the KWSP facility was a real eyeopener for me. It showed what could be done with skilled engineers using 3D printing. Previously, much of this would not have been possible. And if it was, it could have taken months,” comments Stretton.

Set to work

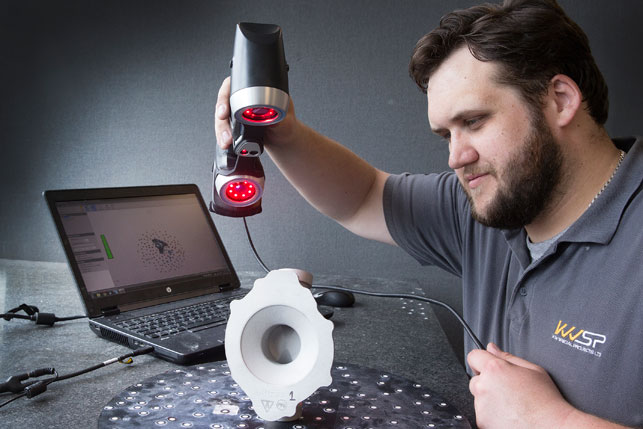

KWSP scanned the original before remodelling the 3D file in Geomagic to add enhanced structural elements

Originally cast in lightweight magnesium alloy, the Alfa’s engine front cover had lost form and function. Unsightly welds were no longer keeping up with the number of cracks that now rendered the component redundant.

Having decided to remanufacture five new covers, the KWSP team set to work digitising the component, 3D scanning the badly corroded engine cover, along with the original water pump and housing.

The original part was 3D scanned using a handheld Creaform Handyscan 700, before being taken into CAD and cleaned up using 3D Systems’ Geomagic software.

The wear was so bad that it was no longer possible to recognise the original distinctive Alfa Romeo logo on the outside of the casting.

Stuart Banyard, head of advanced manufacturing at KWSP, explains that although having the original part to scan, a like-for-like replacement would have been useless. “The original part we had was defective, but this where the real value of our consultancy comes in.

“We were able to create a digital scan of the part – and then crucially, make vital changes to the design to bring it back to its original geometry and functionality.”

The scan data was used as a reference model in the CAD, allowing the design team at KWSP to enhance structural elements within it as required to recreate the component into its intended form.

Eventually, a finished digital asset was created, and a prototype was 3D printed in high performance PC ABS, before committing to the casting process.

Proof of concept

The new and improved engine front cover cast in aluminium

Printed overnight using one of KWSP’s Stratasys Fortus 3D printers, the cover prototype was bolted to the engine to confirm proof of concept.

“This is an important stage of the remanufacturing process as it enables us to make any final changes to the design, without incurring significant cost,” explains Banyard.

On this occasion, the part fitted first time and the project could move onto the production of a final part – now cast in aluminium for added corrosion resistance.

“Without 3D printing, it would have been a lot more difficult to put this great Alfa on the road again,” concludes Stretton.

Thanks to the technology and engineering skills of KWSP, the Tipo 33/3 is back on the grid with spare parts should they be needed, and the digital asset in the CAD file, which can be enhanced and amended should any difficulties arise in the future.

kwspecialprojects.com

The restoration of an Alfa Romeo Tipo 33/3

Default